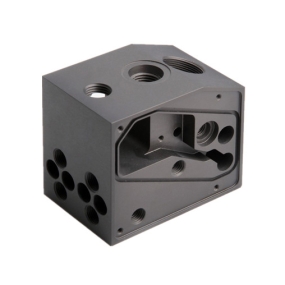

Instrumentum pulchritudinis sunt instrumenta basic pro productione et processione in fabricatibus pulchritudinis. Processum multarum mollium finium est multum complexum, et drillinus est lignum fundamentalissimum et praesentiam quam opus est magistri.

In processione mollium metallorum, requirement ad fluctum precision altissimus est. Conductione precision fluctus bene potest auxiliare meliorem qualitatem mollium et prodere meliorem partem pulchritudinis metallorum qualitatem. Oportus est accuractem markorum, punctionum et drilling cum precision controlare.

1. Control of bottom hole accuracy

First, control the accuracy of line drawing. Examine acutem pinarum altorum per trahendum linearum thinarum et profundum in una parte.

Then, control the precision of the Metal Stamping mold processing punch hole. Durante exemplum puncti, movere exemplum duo centrum cruce markatum grove. Quando est sententia depression is in summo exempli, indicat exemplum est in medio cruce. In hoc tempore, exemplum rectum esse oportet, et operator facile puncti exemplum antequam puncti. Post fluctum oculorum, necesse est verificare si orientatio accura est. Si non satis accura est, necesse est parametros et instrumentos fluctum oculorum ex scratch adjustare. Finally, control the precision of drilling. Primus, use a drill bit to drill a shallow hole in the marked position of the hardware mold, measure the drilling direction and quality to see if it meets the standards. If it does not meet the standards, repeat the adjustment until it meets the requirements. Stamping processing plants needs to pay attention to drill bits with longer cutting edge, which can easily cause the drilling center to be too high. It is recommended to choose drill bits with almost no cutting edge while meeting the drilling requirements.

2. Control of drilling accuracy

Superiora superiora superiora accuracionis inferioris rupis in mollis est fundamentum pro expansione rupis et multo importantium est eligere rationalem methodom accuracionis expansion is mollis.

First, it is necessary to reduce the size of the drilling bit, enhance its automatic centering effect, and continuously reduce the drilling accuracy and cutting force; Secundo, adjust urendam ad fluctum, ut trillis graduam accedet ad portum inferiorem, et faciat modicum adjustationes ad perfectam delendum foram inferiorem de ore drillis. Finally, turn the drilling machine switch and proceed with the mold drilling process.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque