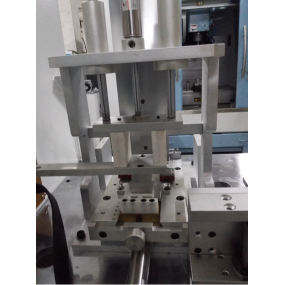

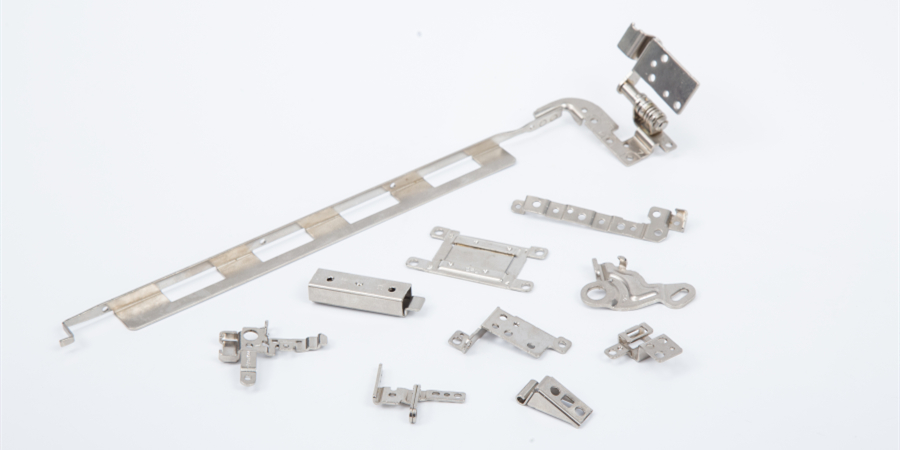

Punching and flanging of stamped parts are generally prepared for the next step of tapping or other processes. In genero processo flangionis et verticionis holarum, seria problemarum, quasi rupturam, burris, et deformationem saepe occurrit. Quomodo fabrica pulveris hoc problem a facit?

1. Partes metallis pulsavi sunt holas fractas.

Haec fenomena prima in intersectione occurrit, ubi punctus fortis concentrati sunt et proni ad ardentes, et etiam a materialibus crudelibus tabuli influentur. Therefore, it is advocatum to use materials with good expansion performance and thin thickness, and to increase the aperture as much as possible during design, which can help reduce the phenomenon of flipping holes and cracking. When designing convex molds, use spherical curvature, add touch area, swap the direction of pre-holes and flip holes, convert the possible location of burns and reduce cracking.

2. Delum pulsavi partis aperientis diminuit.

Aperimenti irregulari fluctus difficile faciant fluctum. Pro analisi rationium, fabricae pulsere invenient quod gapes in convex molda concave sunt fontes problemae, causantes materiae reboundi. Accessio standardissimus est ad adjustendum gapes molda minores quam debilitatem materiae ut verticam aspicientem punctum pertinent in pulsere.  3. Lacta altitudine flipping for Metal Stamping parts.

3. Lacta altitudine flipping for Metal Stamping parts.

Mangum altitudinis foris facile potest inducere ad phenomenum angulorum secendi, profunditatem fluentium sulorum breviare, et connexionis exercitus effectionis. Pro hoc, fabrica metalla precision stampionis processionis, qui pro longo tempore cooperat, festina probationem detect, crescere altitudinem fluentis in tempore, aut tenuere rotam parietem densitatem ut cresceret altitudinem foris.

4. Struktura stampionis metallorum moritur non coincident.

A causa malligationis structurae molae et damnationis materiae facile est materiae fragere et saltare in groveam causantem phenomenum punctionis et dissipationis solitudinis. The negative impact is that it may cause unevency on the surface of the product, resulting in defective products, making after-sales processing difficult and consuming manpower and resources.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque