1,The significance of numerical control

The essence of NC is to actively master the mechanical installation and take measures through the digital information (not the changed digital quantity) under the specific processing method. It has the same nature by continuing the sequence of changed quantity analog. A causa masterii information is in controlo numerico, processi haec mensae breves a computatorio non potest separare. Pro hoc, capacitatem activi masterii per computatorium referitur numericum, specifica ad controlum numericum utilium in processamento instrumentorum machinarum (i.e. instrumentum numericum controllum machinarum). In addition, numerical control is widely used in fields such as measurement, physical and chemical experiments, transmission of materials and information, construction, and scientific governance.

2,Classification of Numerical Control

The NC installation of late stage CNC machine tools consists of various logic components and memory components that form random logic circuits. It is a hardware structure with fixed wiring that implements CNC functions through hardware, known as hardware CNC. Some CNC machine tools implemented using this technique are also called NC machine tools.

Computer Numerical Control, abbreviated as CNC. Systema numerica control a moderna numerica est systema controla numerica quae accipit microprocessores aut dedicatos microcomputatores. Sequentia systemae (software) prior in memoria servata est ut magistrare logicam, possidere functiones regionalis aut partial is numericas controlis, et connect are cum peripheralis peripheralis per interfaces, quae dicitur systemam CNC. Tale instrumenta machinae individualis vocantur instrumenta machinae CNC.

3,CNC machine tool

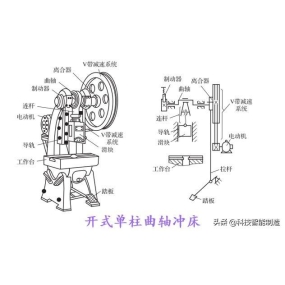

Numerical control machine tool is a new type of electromechanical integrated machining equipment that uses digital information to master the machine tool and perform active machining according to a given static rule.

Numerical control machine tools are the product of the combination of digital mastery skills and machine tools. The numerical control skills of machine tools are achieved through machining techniques such as CNC gantry milling machines. The key to use numerical control skills is in learning and using numerical control machine tools well.

The CNC rate of a country's machine tools reflects the level of its machine tool industry and mechanical manufacturing industry, and is also an important indicator of a country's technological progress. It has significant implications for achieving proactive consumption processes, accelerating technological progress, and slowing down the establishment of modernization. Regnum Xingwang tecnologiae CNC in stratēģisko foco pro industria machinarum et vigorously promot et develops instrumentos CNC machinarum.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque