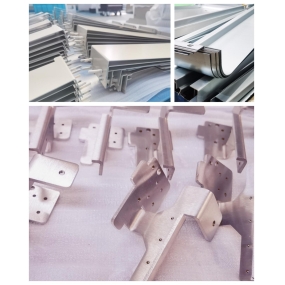

In processione metallorum folii in Shenyang si spatio interiora parva est, sicut interiora fermenta, arma fermenta considerabitur. 6.2 Si mensura est aut aequa 1mm, breviare aut ardere post fermentum est, quod ex deformatione ferentis causa est. Tres principes metodes sprayi sunt sicut:

Lux flatus: potest dividere sub luce, flato luce, et alto luce, cum coating thickness circa 60-90 metrorum et coating thickness circa 90-120 metrorum post spraying

Sandprint: potest subdividere in harenam finem et harenam tunicam. Densita vestimenti spray est circa 50-80 μm, quam circa 80-110 metros ante injekcijam est.

Modellum orangia: in modicum orangiam et magnum parabolam orangiam dividere potest. Densita sprayionis est circa 90-120 μm, et circum 120-150 metros postea injecta est.

densitudo vestimenti superabit sublimem densitudinem

1. Lux placa: Advantationes: Appearantia pulchra, effectus imprensationis bona; Defects: High cost, high spray repair rate, easy to scratch, scratch the surface, unable to repair, and difficult to spray high gloss during the process. Utrum magis possibilis lucem utilizat, maxime in situationibus ubi facile est protrusiones super magnam chassis manere.

2. Sandprint: Advantages: Non facile scratcere, low spraying cost by three; Defectus: oleum exteriorem facile est auferre, et effectus printing non est tam bonus quam orangia.

3. Parabola orangia: Advantationes: Non facile scrutare, bonum effectum impressionis, facile removura olei superficiis, fermenta fermenta paululum maior quam particula harena, sed multo maior quam plaga. Defectus: Aesthetica minima est quam plana.

4. Paint color should be as uniform as possible, using the main product color s of our company to facilitate the supplier's ordering of powder.

5. Proicite unum colorem sprayi, quanto possibile, ut redderet prodigia sprayi, multo meliora tempore processionis, et reddere probabilitatem errorum coationis provisionis.

6. Utrum pulvere argenti evadere debet. Pulver argentum est compoundus argentum continens, et pretium eius duo vice est pulvere regulari. Difficile est ferre et prodere produktionem defectilem.

Contenium artificis ab internet est. Si quaestiones habes, contacta me ut deleam illum!

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque