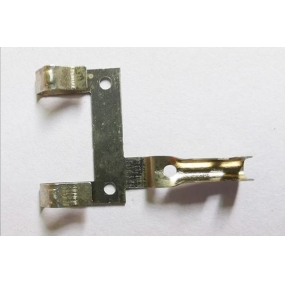

Quid est differentia inter fabricationem metallorum et processionem castientem? Comparamus et analisamus editorem metallicorum lapides precisius. Sheet metal shell processing

Formulae metalla processantur et processantur castantur duae modi diversae processantur metalla. Processo metallis lapides est secendi, stampi, bending, welding, et alia opera technologica in lapidibus metallis ut producent produktos metallos in voluntate forma. Casting processing is the process of injecting molten metal or alloy in a mola to solidify it in a metal product of the desired shape.

First, Sheet Metal Processing and casting processing differ in their processing objects. Metallum lapides processus prima facit lapides metallos, cum densitate generale inter 0,5mm et 6mm, sicut refrigeratores, panes lavantibus, etc. Casting processing is used to process metal blocks or liquids metals, and can produce larger and more complex castings, such as cylinder blocks engine, car frames, etc.

Secundo, techniques processing for sheet metal and casting are also different. Sheet metalla processing generally involves cutting, stamping, bending, welding, and other processes to process metal sheets. Periodibus metallicis generis sunt machinas shearing, machinas punching, machinas bending, machinas welding, etc. Procedentem enim proicientem oportet primum parare molam adequam, conflavere metallum aut allogam, et tunc effundere in molam ut confortaretur et formaretur illud. Equatoria proiectionis et processionis fornaces, molas etc.

In addition, the cost and duration of sheet metal processing and casting processing are also different. Due to the fact that sheet metal processing is mostly done manually and the process is simple, the cost is relatively low and the construction period is relatively short. However, casting processing requires the production of molds, and the process is relatively complex, so the cost is relatively high and the construction period is also relatively long.

In addition, there are differences in product performance between sheet metal processing and casting processing. A causa utilizae lapides metallicis in fabricatione metallicis, produkti generalment leviores sunt, sed rigiditate eorum et resistentia sunt relative pauperes. The castings obtained from casting processing are suitable for situations where they can resist high pressure and impact due to their thick material, good rigidity, and wear resistance.

In addition, sheet metal processing and casting processing also have certain differences in their application fields. Procedura metalla folia amplius est in agris, quales electronica, communicatio, automotiva, aerospace, etc., ad producendum casings electronica, equipamenta communication is etc. Casting processing is mainly used in the fields of automobiles, machinery, construction, aerospace, etc., to produce motor cylinder blocks, automotive chassis, etc.

In summario, sheet metal processing and casting processing are two different methods of metal processing. Formula metalla fabricationis inter cutationem, stampionem, bending, welding, et aliam operationes in lapidibus metallis inducere produktos metallos in voluntate forma. Casting processing is the process of injecting molten metal or alloy in a mola to solidify it in a metal product of the desired shape. Two differ in terms of processing objects, processing techniques, cost and duration, product performance and application areas.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque