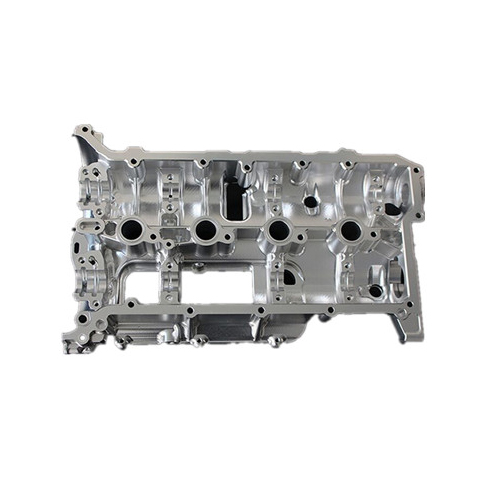

Lingua quinque axis parterum optima machina est quae quinque instrumenta machinae ad processionem utilizat. Praecepta accuracionis valde importantia sunt in quinque partibus machinationis axis. Sequentes sunt aliquid opus accuracii commune: Positioning accuracii: Positioning accuracity of a five axis machine tool should meet the requirements of national or industry standards. Normally, its positioning accuracy should reach IT6 level or higher. Precisio repetitivae positionis: Precisio repetitionis positionis instrumenti quinque axis machinae est etiam indicator gravis pro mensurare precision sua. Precisio positionis repetitionis normale non excedet 1,0 μm. Machining accuractia: The machining accuracy of five axis machines is usually verified by machining test specimens. Precisio dimensionalis et precisa forma specimenorum processorum conformetur ad opus drawingorum. Stabilitate: quinque instrumenta machinae ad axis stabilia manere debet in processione longo tempore ut non efficiat accuracionem machinae a causa factoribus, quales temperatura et vibratione. Tool wear: Tools used in five axis machining should be regularly inspected and replaced to ensure the roughness and dimensional accuracy of the machined surface. At the same time, operators need to undergo professional training and skills enhancement, master the correct processing methods and techniques, and avoid processing errors caused by incorrecta operation.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque