Undoubtedly, five axis machining technology is becoming increasingly widespread in the field of mechanical processing, and has even become closely related to people‘s daily lives. However, the cutting tools we see in machining manufacturers are still relatively simple flat bottomed cutters and ball end mills. This difference was not significant more than a decade ago, and everyone thought it was natural. In fact, can the shape of five axis machining tools only be so simple? The answer is negative. Five axis machining centers can perform complex linkage operations and support the use of more flexible machining routes to improve machining efficiency. Cutting tool manufacturers have gradually withdrawn from a series of large arc new milling tools. By using various convenient and reliable machining strategies more reasonably, they can fully tap into the machining potential of five axis machine tools;

1, Large arc milling cutters and superstring precision machining technology

1, Large arc milling cutters and superstring precision machining technology

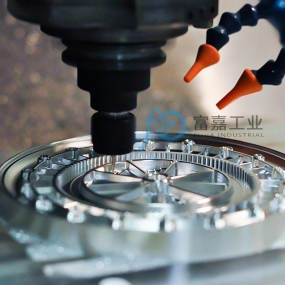

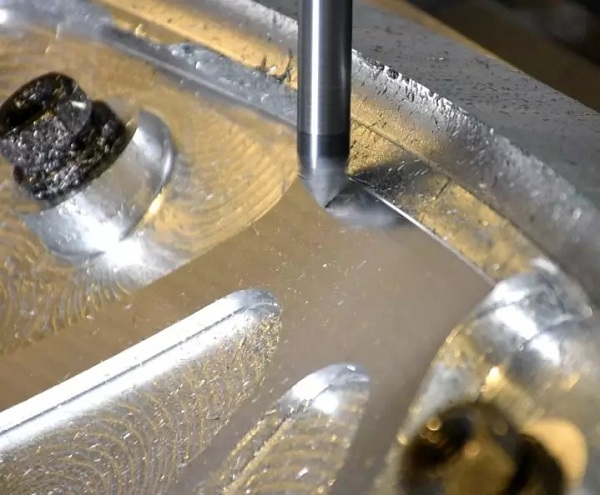

The large arc milling cutter, also known as the drum milling cutter or parabolic milling cutter in the industry, can perform surface machining on various complex parts, especially in the mold industry. Reasonable machining route programming is the key to effectively using large arc cutting tools. In machining route planning, it is necessary to base on the geometric shape of the cutting edge of the tool, so that the special shaped cutting edge in the tool can contact the workpiece surface at a suitable angle during the cutting process;

In order to meet this requirement, tool manufacturers have collaborated with CAM software developers to develop a programming tool that can implement this type of tool design concept. The future of CNC precision machining technology is quietly approaching. Mastercam‘s superstring, Mastercam‘s superstring presumn machinum machinum machinum, est based on the exact contour of a circular arc cutting tools in the machinum process of works works with a relatively high surface quality. By controlling the cutting path of the tool to achieve appropriate angles and precise fitting of the workpiece contour shape, i the machining cycle time can be greatly reduced under the premium of a superficial superficium. Large circular arc cutting tools basically need to be used in conjunction with five axis CNC machine tools, especially in the field of mold processing, to maintain the required angle cutting. Mastercam‘s superstring is a superstring. Mastercam‘s superstring tecnologia machinationis precision is potest organicament formam instrumenti cum exercitus motion complexis quinque instrumenti machinatis axis, maxime improvine efficabilitatem machinatis precisionis;

2, How do you view these new types of milling cutters

Quam rolum software CAM ludit? When the concept of large arc cutting tool s was first proposed, CNCSoftware began to engage in-depth technical exchanges with tool manufacturers for collaborative research and development. CNC Software engineer Jesse Trinque even participated deeply in the development of Mastercam‘s programming solution for large arc cutting tools. What are his views on this new type of milling cutter? Quid est rolus software CAM in hoc nova concepto secessionis?

Praeterito, software CAM non modellavit instrumenta precisa secere, dixit.

Praeterito, software CAM non modellavit instrumenta precisa secere, dixit.

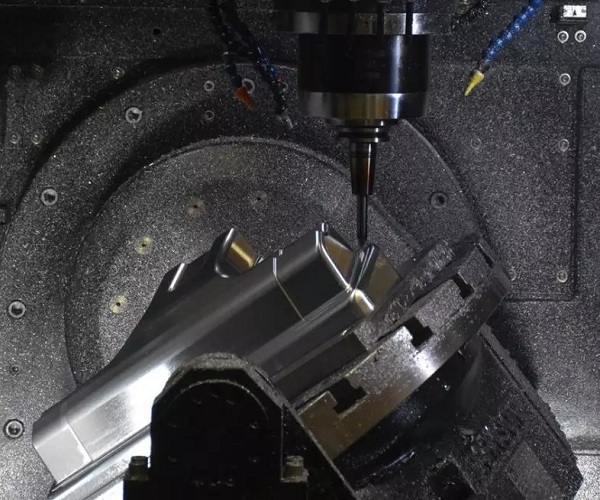

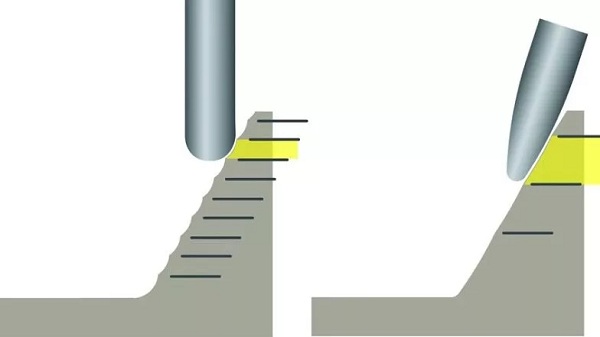

The best report on the investment in new technology research and development is the significant improvement in precision machining efficiency. The special curvature cutting edge used by large arc cutting tools is used for precision milling along the surface contour. When using ball cutters for precision machining, the curvature of the cutting point is first compared to the radius of the tool. In contrast, large arc cutting tools such as elliptical milling cutters and cylindrical milling cutters can use very large curvature cutting edges on small radius tool bodies for machining;

CAM software est crucial ad usum instrumentum circularum arc a, et ad custodiendum mensuram rectum est, requit vias mensuram ad omnem diversam typum arca segmenti circularum ad instrumentum circularum similis similis ad instrumentum circularum.machinationis precision. Quando superficie machinata est relative magna, tempus machinationis multo longum fiat. Utrum magnum arc a circularum cutor simile qualitatem machinationis cum maiore potest attingere. In hoc modo, tempus ciclis significa compressus potest. However, when using a large arc cutting tool, it is necessary to keep the cutting edge in contact with the workpiece in an appropriate angle so that the contour of the large radius cutting edge can play a role;

CAM software est crucial ad usum instrumentum circularum arc a, et ad custodiendum mensuram rectum est, requit vias mensuram ad omnem diversam typum arca segmenti circularum ad instrumentum circularum similis similis ad instrumentum circularum.machinationis precision. Quando superficie machinata est relative magna, tempus machinationis multo longum fiat. Utrum magnum arc a circularum cutor simile qualitatem machinationis cum maiore potest attingere. In hoc modo, tempus ciclis significa compressus potest. However, when using a large arc cutting tool, it is necessary to keep the cutting edge in contact with the workpiece in an appropriate angle so that the contour of the large radius cutting edge can play a role;

Using a much larger tip arc than a ball cutter, large arc cutting tools can perform precision machining more interestingly. The taper type cutting tool here is an extreme case, where its cutting edge looks basically straight. This type of tool requires very precise meshing angles for precision machining. What kind of contact angle is needed for precision machining? Jesse dixit quoniam instrumenta elliptica concussionis unusquisque 15 graduum inter facientem regionem contactorum constituuntur, et form a taperae magis limitata est. Variatio anguli meshing eorum 0,1 graduum non potest excedere. Contradictum, angulo instrumenti pilae intra regionem suam motion factum infinitus est. Hoc est propter quod instrumenta pilae in quasi omnes centros machinarum utilizatur, sed magna instrumenta arcae concussionis in quinque axis machinarum CNC utilizatur.

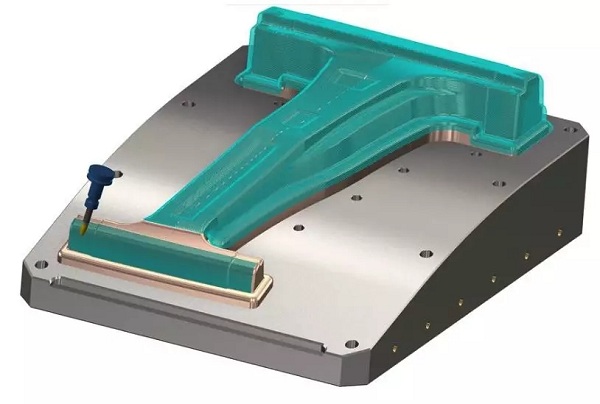

@000He also said that circular arc milling cutters are suitable for milling open large curved surface features on workpieces, and such as how to use lens type cutting tools to precision mill the step are a of the mold cavity, and how to use tapered or elliptical cutting tools to precision machine the sidewall of the mold core. Generally speaking, using a ball cutter to process these areas may take several hours, while using a combination strategy of centralized large circular arc milling cutters can compress the processing time to within an hour. Comparant cum cursore pilae, quomodo magnus cursore arcae tempore servat? Using a larger blade tip curvature, it is possible to achieve the same residual ridge height with a larger step increment. This approach not only improves productivity, but also results in components with better surface smooth;

Dixit autem superstring precision machina non solum pro fabricatione, sed etiam pro partes aerospace et implantis medicinis cum magnis superficiis functionibus. Especialmente pro partes aerospace et medicinis, multae iam processuntur per quinque machinas CNC axis. Aliquando socii assistimus in facie componentibus titanium alloy genus, dixit. Haec parte cum instrumento machinae quinque axis proceditur, et tempus machinae precision orijinalis tempus erat 70 minutis. Utimus magnas arc a s cutting tools combined with Mastercam‘s superstring precision machining technology to shorten the precision machining cycle time to 10 minutes, and its surface quality is even better than before

Cucutor pilae adhuc gravissimus est. Aliquando, potest aliquid parvus gapus esse in partes complex is, et tantum cutor pilae intrare in gapum in angulo adequa pro machina precision. Vere, Dominus Jesse dixit, quia hoc est realitatem, quam utiliserum oportet cognoscere quando accepto conceptum machinae precision novorum instrumentorum et corum.

A forte, a forte, a forte, a forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, et forte, forte, forte, et forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, forte, "dixit. In intellectu precision machining technology of superstring, different shapes of cutting tools and different cutting paths can be selected according to the characteristics of different areas in the cavity during programming, in order to complete precision machining with higher efficiency and lower cost

Sin opinione, quo utilia multo complexe cutting-edge forma est in fortitudine communicationis.The continuous evolution of tools can combine the complex cutting paths that CAM software can achieve with the complex CNC machines movements that five axis machines can achieve, which is a very important factor in improving precision machines. He also said that many tool manufacturers are also introducing more efficient and different shaped tools. Mastercam no longer defines tools as simple shapes, but as an indispensable and important component of efficient precision.machina;

Sin opinione, quo utilia multo complexe cutting-edge forma est in fortitudine communicationis.The continuous evolution of tools can combine the complex cutting paths that CAM software can achieve with the complex CNC machines movements that five axis machines can achieve, which is a very important factor in improving precision machines. He also said that many tool manufacturers are also introducing more efficient and different shaped tools. Mastercam no longer defines tools as simple shapes, but as an indispensable and important component of efficient precision.machina;

A few years ago, it has continuously updated and optimized its production processes and introduced the high-precision CNC machines. Currently, a set of machines, a set of CNC machines, a set of CNC machines, a set of CNC machines, a set of CNC machines, a set of CNC machines, a set of CNC machines, and a set of CNC machines, a set of CNC machines.manipulare precision machining tasks of various materials and complex structural components.

A few years ago, it has continuously updated and optimized its production processes and introduced the high-precision CNC machines. Currently, a set of machines, a set of CNC machines, a set of CNC machines, a set of CNC machines, a set of CNC machines, a set of CNC machines, a set of CNC machines, and a set of CNC machines, a set of CNC machines.manipulare precision machining tasks of various materials and complex structural components.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque