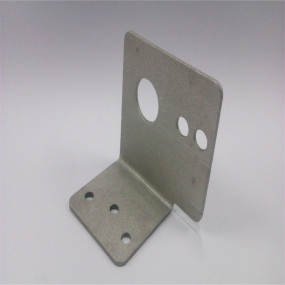

Stainless steel machining refert to the use of mechanical processing equipment such as CNC machine tools, milling machines, and drilling machines to process stainless steel materials in order to obtain parts of the desired shape and size. Stainless steel machining needs to pay attention to the following points: 1. Tool selection: Stainless steel materials have high hardness, difficulty, and wear resistance, so suitable tools need to be selected for machining. Generally speaking, stainless steel machining requires the use of hard alloy cutting tools or high-performance ceramic cutting tools. @0002. Coolant selection: Stainless steel materials are prone to high temperatures during processing, i so coolant is needed to reduce the temperature and prevent workpiece deformation or cracking. Common cooling fluids include cutting oil, emulsion, etc. 3. Selection of cutting parameters: The selection of cutting parameters for stainless steel machining is crucial for machining quality and efficiency. Parametri, quasi velocitas, fluctus, et profunditates secere, necesse sunt rationale electi based on the performance of the machine tool and cutting tool, as well as the material and shape of the workpiece. 4. Processing sequence and clamping method: i The processing sequence and clamping method of stainless steel machining also have a significant impact on processing quality and efficiency. Oportum est adequatum modum clampionis et sequencem processi secundum materiam, formam et processionem opus ut accuractem et processionem effectivitatem opus assecurat. 5. Trepta superficie: superficie steelae indestructi post machinas usus tractatur ut desideratum aspicientem et qualitatem acciperet. Common surface treatment methods include polishing, wire drawing, sandblasting, etc.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque