Mainly explain the functions of each button on the operation panel of the machining center, so that students can master the adjustment of the machining center, the preparation work before processing, and the methods of input and modification of the program. Finally, taking a specific component as an example, the basic operation of machining parts on a machining center was explained, giving students a clear understanding of the operation of machining centers.

1, Processing requirements

1, Processing requirements

Processe partes sicut in sequente figura monstratae sunt. Materium component is LY12 est, quam singulam partem produit. Vasco partee in magnitudine machinata est.

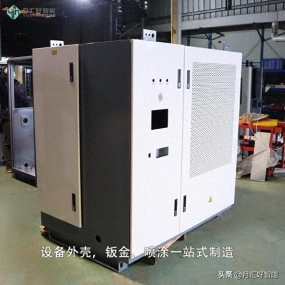

Equipment selection: V-80 machining center

2, Preparation work

Complete relevant preparation work before processing, including process analysis and route design, selection of cutting tools and fixtures, programming, etc.

3, Operation steps and content

3, Operation steps and content

1. Power on, manually return each coordinate axis to the machine origin

2. Tool preparation

Select a Φ 20 end mill, a Φ 5 center drill and a Φ 8 Fried Dough Twists drill respectively according to the processing requirements, and then clamp the Φ 20 end mill with the spring collet handle. The tool number is set as T01, and clamp the Φ 5 center drill and Φ 8 Fried Dough Twists drill with the drill collet handle. The tool number is set as T02 T03, Installa instrumentum inventoris in manipulo pulvere cargae et numerum instrumenti T04 pone.

3. Manually place the tool holder, and which has already been clamped, into the tool magazine

1) Enter "T01 M06" and execute

2) Manually install T01 tool on the spindle

3) Sequere gradus supra ad locum T02. T03 and T04 in the tool magazine in sequence

4. Clean the workbench, install fixtures and workpieces

Clear the flat mouth vise and install it on a clean workbench. Use a dial gauge to align and level the vise and then install the workpiece on the vise.

5. Utrum instrumentum pone determine and input the parameters of the workpiece coordinate system

1) Uter inventor termini ut instrumentum alignet et determinare valores nullos bias in directionibus X et Y. Adjuste valores bias nullos in directionibus X et Y.

Introducio in systemam coordinatum operationis G54, ubi nullus in directo Z positus est 0;

2) Pone positor Z-axis super superficiem partes operae, call out No. 1 tool from the tool magazine and install the spindle, use this tool to determine the Z-direction zero offset value of the workpiece coordinate system, and input the Z-direction zero offset value into the length compensation code corresponding to the machine tool. The "+" and "-" numbers are determined by G43 and G44 in the program. If the length compensation command in the program is G43, enter the Z-direction zero offset value of "-" into the length compensation code corresponding to the machine tool;

3) Uter eiusdem gradibus ut inveneris Z-direction nullus gradus ex instrumentis 2 et 3 in correspondent longitudine codica compensationis instrumenti machinae.

6. Programma procedentis ingressus

Transferte programmam machinationis generatum computatorium in memoriam systemae CNC instrumenti per cablum datum.

7. Debugging and processing programs

Debugging is carried out by translating the workpiece coordinate system along the+Z direction, i.e. lifting the tool.

1) Debug the main program and check whether the three cutting tools have completed the tool change action according to the process design;

2) Debuere three subroutines qui correspondent ad tres instrumenta secessionis, et verificare si actiones instrumentorum et semitas machinationis rectas sunt.

8. Automatic processing

After confirming that the program is correct, restore the Z value of the workpiece coordinate system to its original value, set the fast moving magnification switch and cutting feed magnification switch to low gear, press the CNC start button to run the program, and start machining. Attention ad observandum viam instrumentorum et distancem remanentem moventium dum procedura machinatorium.

9. Remove the workpiece for inspection

Select a vernier caliper for size inspection, and conduct quality analysis after inspection.

10. Redige locum processionis

11. Claude

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque