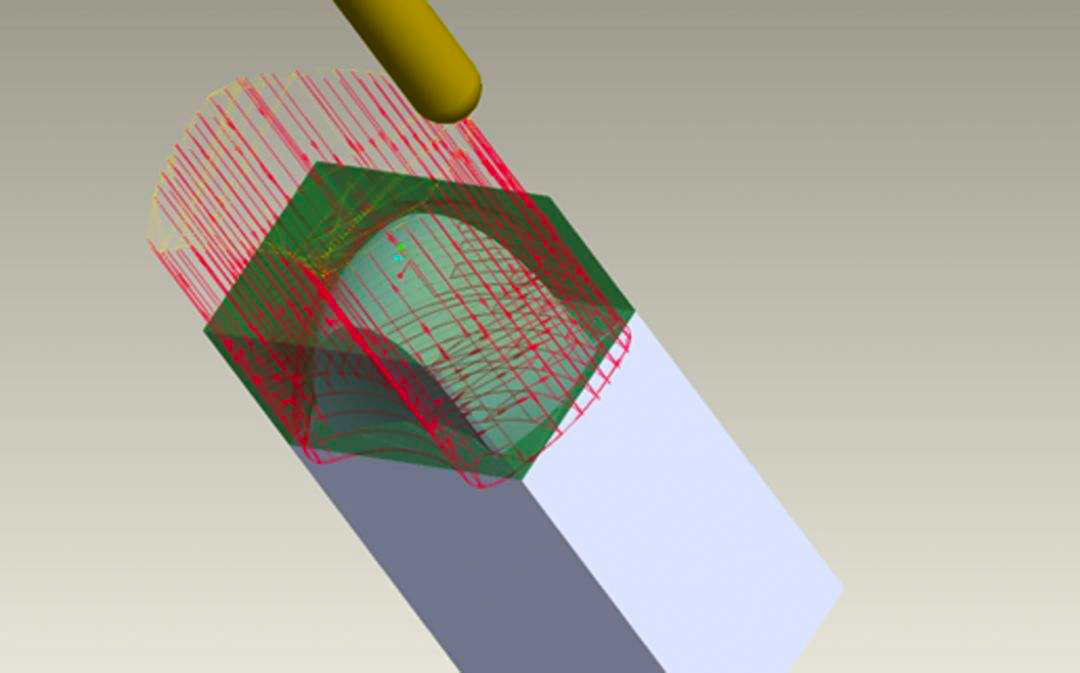

1. Using computer simulation system

With the development of computer technology and the continuous expansion of CNC Machining teaching, there are more and more CNC machining simulation systems, and their functions are becoming increasingly perfect. Therefore, it can be used for preliminary inspection procedures, watching the movement of the tool to determine whether there is a possibility of collision.

2. Utilizing the built-in simulation display function of CNC machining centers

2. Utilizing the built-in simulation display function of CNC machining centers

Usually, more advanced CNC machining centers have graphic display functions. Post inpositionem programae, function simulation is grafica vocabitur ad observandum trajectorium motionis instrumenti in detalio, ut probaret si existet possibilia collisionis inter instrumentum et fabricationem aut fixturam.

3. Utilizing the idle operation function of CNC machining centers

Functio functionis CNC machinatorium centri non functionis ad rectum viae instrumenti probare potest. Post ingressum est program in centrum machinarum CNC, instrumentum aut articulum installare potest, et tunc button operation is inactivitatis pulsat potest. In hoc tempore spindle non rotatur, et tabula operationis automaticamente secundum trajectorium programmae executur. In hoc tempore, invenietur si instrumentum potest colligi cum articulo aut fixtura. Sed in hoc caso necesse est certare non potestatem facere instrumenta succidere quando fabrica instalata est; Installantes instrumentos succidentes, opus installare non potest, alioquin collisiones occurrent.

000@0004. Utilizing the lock function of CNC machining centers

Typical CNC machining centers have locking functions (full lock or single axis lock). Postquam ingressus est program, claude axis Z et determina si collisio occurrit based on the coordinate values of the Z-axis. Aplicatio huius funktionis evadere instrumentum mutandum et alteram operationem, alioquin program non potest transire.

5. Configuratio systemae coherentiae et compensationes instrumentorum recta est

When starting the CNC machining center, it is necessary to set the CNC machining center reference point. Systema coordinatus functionis centri machinae CNC coherentur cum programmatione, subito in oriente Z-axis. Si error est, possibilia magna est miling cutor collidit cum opera. In addition, the setting of tool length compensation must be correct, otherwise it will either result in empty machining or collision.

6. Improvere scientias programationis

Programmatio est gradus crucial in machinationibus CNC, et meliora scientiae programationis potest multo evadere collisiones inutiles.

For example, when milling the inner cavity of a workpiece, the milling cutter needs to quickly retract to a position 100mm above the workpiece. If N50 G00 X0 Y0 Z100 is programmed, the CNC machining center will link the three axes, and the milling cutter may collide with the workpiece, causing damage to the tool and workpiece and seriously affecting the accuracy of the CNC machining center. In this case, the following program N40 G00 Z100 can be used:; N50 X0 Y0; Instrumenta primum ad positionem 100mm supra opus, et postea revertere ad programmationem nullum punctum, ut non collideretur.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque