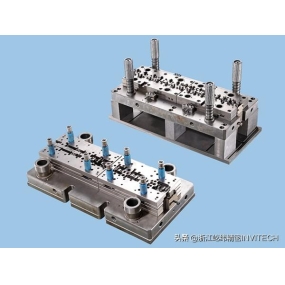

Procedurae fabricationum metallorum industrium prima sunt cutatio, bending, welding, et ecclesiae. Different sheet processing companies may have some differences in their processes, mainly reflected in the following aspects:

First, the cutting process. Cutting is the first step in Sheet Metal Processing, and common cutting methods include shearing machines, CNC flame cutting machines, CNC plasma cutting machines, etc. Different companies may choose different cutting equipment, and their cutting accuracy and efficiency may vary.

Secundum, procesus bending. Bending is the process of bending cut sheet metal parts according to design requirements. Common bending equipment includes CNC bending machines, hydraulic folding machines, etc. Differentibus firmae potent diversa arma bending eligere, et accuractia et effectivitate eorum processura etiam varia potest.

Again, welding process. Welding is the process of connecting different components or sheet metal parts together through welding techniques. Common welding methods include argon arc welding, gas shielded welding, spot welding, etc. Different companies may have different welding equipment and techniques, and their welding quality and speed may also vary.

Again, welding process. Welding is the process of connecting different components or sheet metal parts together through welding techniques. Common welding methods include argon arc welding, gas shielded welding, spot welding, etc. Different companies may have different welding equipment and techniques, and their welding quality and speed may also vary.

Post Z, congregatio processus. Asamblea est procesus multitudinis componentibus procedentibus combinationis et congregationis secundum diagrammas designationis ad finem produktum formandum. The assembly processes of different companies may vary, with some companies using automated assembly lines and others using manual assembly methods.

Overall, the process of sheet metal processing companies mainly depends on their equipment, technology, and management level, and different companies may have different process characteristics and advantages. Therefore, when choosing a sheet metal processing company, it is necessary to select suitable partners based on product requirements and personal needs to ensure product quality and delivery time.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque