Inter omnes factores causantes defectum molae, materia et calefactio molae cogitant circa 70% ex toto, facti principes efficientes mensam vitae molae. Pro hoc, cum plantaverint totum fabricationem fabricationis molorum, seleccio fabricatorum molorum et appropriatio fertilitatis procedentium fertilitatis multo importa sunt fabricatorum pulsere.

Due diversis conditionibus operationis variorum molorum, sunt etiam differentia in requiribus materialibus partibus utilis in molda operationibus.

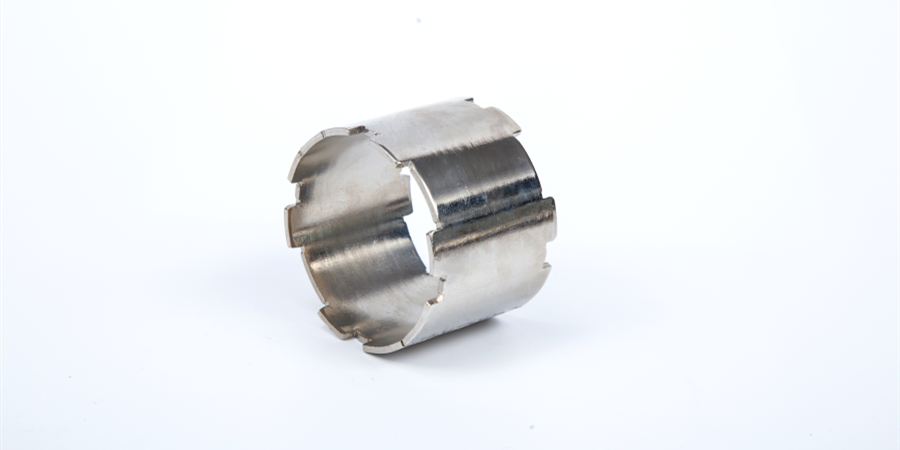

1. Requirements for punching die materials

For the working parts of thin plate punching molds, high wear resistance and hardness are required, while for thick plate punching molds, in addition to high wear resistance and compressive yield point, high fracture resistance, high bending strength, and resistance are also required to avoid mold fracture or blade breakage. Requirements for Deep Drawing Die Materials

Materium partium operation is fusilis necesse est esse antiadhesionis (antimors), alta resistentia et duritia, certa resistentia fortia, et bona procedentia, et minima deformatio dum calore tratione.

3. Requirements for Cold Extrusion Mold Materials

Mold operation parts are required to have high strength and hardness, high wear resistance, and a certain degree of resistance to avoid impact breakage. Due significant increase in temperature during compression, it should also have a certain degree of heat fatigue resistance and thermal hardening.

Reasonably selecting mold materials and implementing the correct heat treatment process based on the requirements of stamping mold operation parts is the key to ensuring the service life of the mold. For molds with different purposes, stamping processing plants can summarize and consider factors such as their operating conditions, stress conditions, the function of the processed material, production batch size, and production rate, and focus on the various functions required above, and then make selections for steel grades and heat treatment processes.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque