Precision Sheet Metal Processing is an important manufacturing process widely used in various fields such as electronics, health care and automotive. In adventum Industriae 4.0 era, automatia et intellectus meliora graduam graduam graduantur tendentia metallis processionis lapides precisionis. This improvement can improve production efficiency, reduce costs, ensure product quality, and adapt to special needs. Haec articulus discebit quomodo automaticam et intellegentiam artificium precision processationis metallorum melior esse.

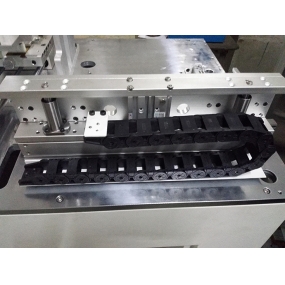

First, automation improvement is the key to achieving automation in precision sheet metal processing. Introducente equipamenta automatica et robotas, operationes hominis et machinae effectuale integratae sunt. Instrumenta automatica potest completa proceduras cargam et discargam, processamentum, inspectionem, packaging, etc. parterum, ut reducatur effectum factorum hominum in processionem procedentibus et multo improvint productivitatem. Meanwhile, automated equipment can also provide precise control and monitoring, ensuring product consistency and stable quality. Claves technology for automation improvement include automation sensors, automation control systems, robot technology, etc. Configurat et applicare hoc technologiam, Alta gradus automationis in fabricatione metallorum precisio potest.

Secundo, meliora intellegentia est clave intellegentiae lapides metallis processionis attaini. Introducente inteligente tecnologia, procedura machinationis intelligentior, flexibilis et adaptivus est. Intelligent technology mainly includes machine vision, artificial intelligence, big data analysis, etc. Firstly, machine vision technology can monitor and analyze various parameters and changes in real-time during the machining process, enabling automatic control and correction of the machining process. Secunda, i artificial intelligence technology can provide more intelligent and efficient decision-making and control by learning and simulating human thought processes. Big data analysis technology can analyze and mine a large amount of data obtained during the processing, providing decision support and predictive capabilities for optimizing the production process. Ut hoc inteligentem technologiam rationale applicere, processione metallis precisius inteligentiam et flexibilitatem habere potest.

In addition, the following aspects can be considered for automation and intelligent improvement of precision sheet metal processing.

In addition, the following aspects can be considered for automation and intelligent improvement of precision sheet metal processing.

First, optimize the production process and layout. Redsigning the production process and workshop layout, unnecessary transportation and waiting time can be reduced, improving production efficiency and resource utilization. Meanwhile, arranging the positions of equipment and workers reasonably can reduce the occurrence of traffic and collision accidents.

Secundo, establish a comprehensive data management system. Precision sheet metal processing involves a large number of process parameters, product specifications, and quality data, which are crucial for optimizing the production process and improving product quality. Therefore, establishing a comprehensive data management system can facilitate the collection, storage, analysis, and utilization of this data, providing strong support for the optimization of the production process.

Again, cultivate and improve the skills level of employees. Quando introductionem automaticae et inteligentis tecnologiae multo dimittere potest opus manus operationes, adhuc necessitatem est ad quaecum personnel technicae ad custodiendum equipmentorum, administracionem datum et operationem intelligentiam systemae exercitum. Pro hoc, praefectionibus et praesentibus optimis praebentibus potest meliorare nivellum et opus qualitatem suam, efficabilitatem opus et productionem suam.

Post Z, conforta et meliora control qualitatis. Precision sheet metal processing requires highly rigorous and accurate quality control to ensure product accuracy and consistency. Therefore, establishing and improving a quality control system, including quality control measures and processes throughout the entire process from raw material procurement to product production, can improve product quality and reduce defect rates.

In summario, automatio et intellectus meliora lapides metallorum processionis precisius est in maxima gravissima tendentia. By applying automation and intelligent technologies reasonably, optimizing production processes and layouts, establishing a comprehensive data management system, cultivating and improving employees‘ skill levels, strengthening and improving quality control, we can effectively improve production efficiency, reduce costs, ensure product quality, and adapt to special needs. Credo quoniam in futuro disveloppamento superior nivellos automationis et intellegentiae possidebit.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque