Today, the chassis and cabinet sheet processing editor will take you to understand the industry standards for Sheet Metal Processing.

The industry standards for sheet metal processing mainly include the following aspects:

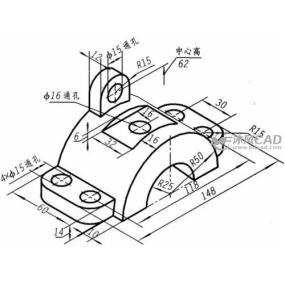

Accurabilitatem nivellum et tolerantia dimensionalem: Accurabilitatem nivellum processionis metallorum lapides usual in nivellum A, nivellum B et C dividitur. Haec nivella ad standard JISB2201 convenit. The dimensional tolerance shall comply with the provisions of GB/T9124-1988 "Shape and Position Tolerance".

Accurabilitatem nivellum et tolerantia dimensionalem: Accurabilitatem nivellum processionis metallorum lapides usual in nivellum A, nivellum B et C dividitur. Haec nivella ad standard JISB2201 convenit. The dimensional tolerance shall comply with the provisions of GB/T9124-1988 "Shape and Position Tolerance".

Superficie angustia: Superficie angustia diversorum typorum metallorum executa est secundum provisions in Tabula 1.

Bending degree: The bending degree of metal sheet shall not exceed 0.1% of the corresponding external dimensions of the parts.

Bending requirements: When bending metallic sheets, the distance between each point on the outer edge of the opening should not exceed 0.3d; Cum benderetur sine punctibus, non excederet distancia inter angulum aperturi et parietem interiorem intrinsecus 0,5d.

Treatione terrae: Quando densitate lapidis metallis minor est quam 6mm aut maior quam 25mm, tratio maris effecta est.

Praecitate et perpendicularitate: deviationes perpendicularitatis simplicitatis et perpendicularitatis platearum asymmetricum tenentium cum densitate inter 10-15mm et nulla robusta ferentia sunt 0,2d et 1,0d respectively; Quando symmetry platearum rectangularum cum densitate inter 16mm et 30mm pauperum est, consilium est modo drawing is singulae ad fabricationem usare.

Test method for non-metallic materials: The tensile test method for non-metallic materials should comply with the relevant provisions of GB/T1392-1993 "Tensile Test Method for Metallic Materials at Room Temperature".

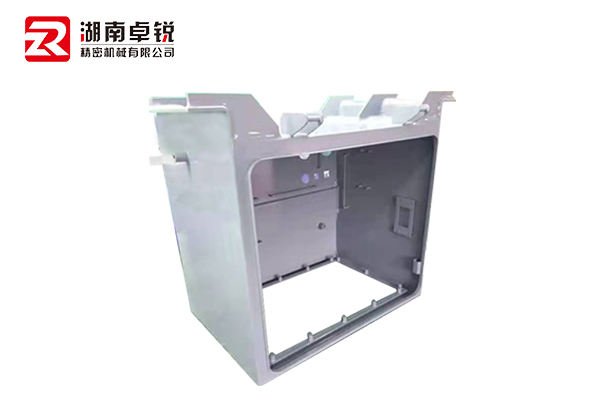

In addition, sheet metal processing also includes standards for multiple processes steps, such as CNC cutting, CNC punching, CNC bending, welding, spraying, packaging, labeling, etc. Xiangtan Zhuorui Precision Machinery Co., Ltd. specializes in sheet metal processing, laser cutting, numerical punching processing, CNC bending, sheet metal shell processing, welding processing, as well as various communication equipment cabinets, chassis, industrial electromechanical equipment supporting EMAR cabinets, control cabinets, consoles, pressure furnace welding, railway locomotive parts welding processing, and complete sets of electrical control system assembly. Omnes ad consilium advenisti.

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole