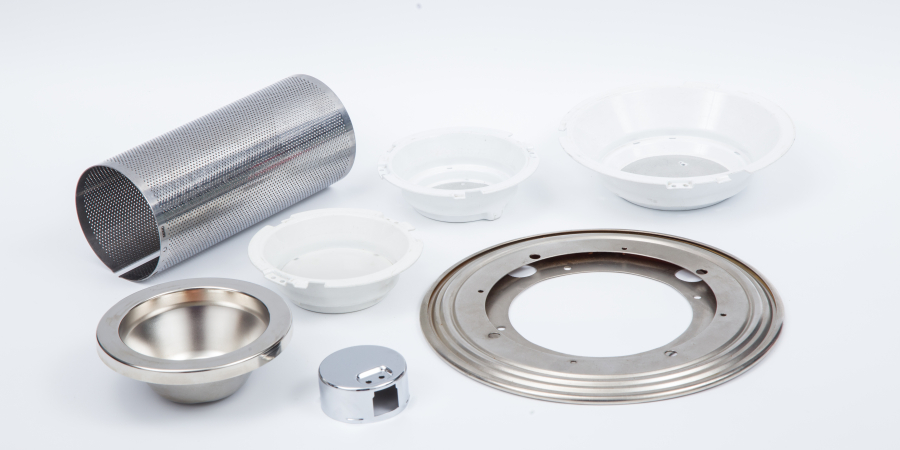

Materiales, quae in fabricatione partium metallicorum stampionis, generalmente dependant on the requirements of production design and functionality. When selecting metallic stamping part materials, it is necessary to scientifically and reasonably evaluate the stamping function of the materials, correctly grasp the connection between sheet Metal Stamping function and stamping process forming. Below are a few metal stamping part materials:

1,

Pellicum calidum rollatum est altum qualitatem quadringulum carbon cum fractione massae carbon is 0.1% ad 0.15%. Pellicum calidum carbon est et in pretio malitior est comparatum ad plateas calidum rollatum steelam. Debitudinem et fortitudinem habet, ideo habet amplius varium applicabilitates in campo stampionis, sublime in partes stampionis automaticam hardware. Platae calidum rollatum ferunt substantiam proportionem et ususque in trabam crustum, trabam longitudinalis, partibus chassis structural, partibus subtitus, et partes cum praecepta magna fabricationis formabilitatis.

2, Placeta calida calida

sunt multae metodes classificationis plateis frigidis vestibulis quae dividentur in vitrum coquens et ferrum occisum et ferrum semi occisum secundum metodes deoxidationis secundum typum fertilis et compositionem fertilis dividere potest in altum fertilium carbonum, altum fertilem fertilem fertilitem, phosphorum fertilem fertilem fertilem fertilem carbonum, etc. secundum gradum fortitudinis dividetur in gradum fortitudinis et altitudinem fortitudinis secundum gradum stampionis aut propositum dividere potest in usum generum, gestationem, utilitatem stampionis profundi, utilitatem stampionis profundi extra et utilitatem stampionis profundi ultra profundi.  III. Stainless Steel

III. Stainless Steel

Stella Stainless refert to high alloy steel with a chromium mass fraction of over 11%. Its main characteristics are high corrosion resistance and heat resistance, as well as rust resistance and external luster. Stainless steels used in stamping include ferritic stainless steel, austenitic stainless steel, and martensitic stainless steel. Functione ferritis steel is ferritis calidissima est quasi plateae calidissimi rotae steeli. In productione steeli huius calidissimi texturae etiam a calore rullendo, frigido rullendo, et annealingo, quae habet extraordinaram functionem dulcis drawingis. But its hardening index is about 92, and its elongation is 25%~30%, both are smaller than austenic stainless steel, So its elongation type stamping forming function is poor; inter eos ferritius steel stainless representatus a SUS430 et steel austenitica stainless representatus a SUS304 potest ad formandum stampionis utilizat;

4, Coated steel plate

In order to prevent corrosion of metal stamping parts by various acidic or alkaline substances such as air, moisture, water, oil, etc., countries such as the United States and Japan have proposed the goal of five years of corrosion resistance and ten years of resistance to through-hole rust on the exterior of automobile bodies, and have developed new coated steel plates. Nunc, multae raedae domus etiam inter diversas specificationes et quantitates platearum vestitum necessitat. Antipulveria et pulveria proprietates platearum vestrorum in stampionibus efficient formabilitatem suam. Duo genus vestimenti sunt: primus est formacio particularum propter defectum interioris vestimenti, i cum dimensionibus particularum generis minoribus quam densitatem vestimenti, et formam pulvere, notum quam pulvere. Secundus est formatio flake quasi particularum a causa de defectu adhesion is inter vestimentum et substratum. Dimensio particularum simile est generale aut maior quam densitatem vestimenti, et in flaco simile, quod appellatur detachment. Dimensio et method coating pulverisation et detachment sunt relati ad factores, quales coating composition, function, structure, thickness, and forming conditions.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole