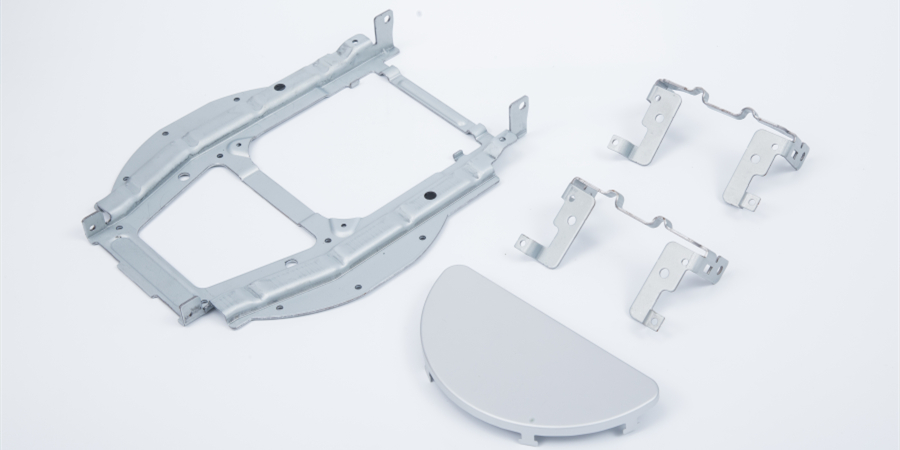

Automotive hardware stamping parts are generally obtained by punching the required holes and profiles on the material. The orientation and shape of the holes and profiles are required to be consistent with the drawings, with errors within the industry‘s specified tolerances. The appearance should ensure outstanding performance without significant defects such as burrs, sharp corners, and scratches. Holes and profiles are the primary elements of automotive hardware stamping parts. Secundo requisiis corporis vehiculi et partibus pulseris, holae super partibus pulseris in tres categorias divisae sunt: holae apparatus, holae positionis, et holas procedere poterunt.

1. Pelles apparatus referunt ad holas requirentes ut instarent chassis, interior et accessoria in corpore raedarum, quae sunt in parte standard apparatus. Dimensio et forma per componentes standard iuxta propositum determinantur; Haec sunt omnibus tres typis holarum: holas quadriae, holas quadriae, et holas longae. Quadriae holas quadriae sunt, quasi calas quadriae, quasi calas quadriae, et holas longae, quasi calas quadriae sunt, et calas quadriae, quasi bolas. Interior diameter melior est 0,5mm maius quam exterius diameter calis, quasi bolas. A hola cum circulare similare similare vocatur in circulare. orientatio huius typis holae est valde precisa, et non est adjustationem, quando accessoria instatur. Pro hoc, longae rupae sunt magissississi usus utili. A causa requibus vehiculi corpus et stampionis, forma ruporum longorum planata est composere ex quadrato et duo semicirculo, quod assegurat ut sit aliquid adjustationem quando accessoria installatur, i ut accessoria accura et convenienter installatur in corpore vehiculi.  2. Positioning holes refer to the holes used in car body welding to locate automotive stamping parts. Due the requirement for precise orientation during car body welding, positioning holes are mostly circular holes, and there are also very few positioning holes that are planned as squares due to special requirements. This type of hole requires precise orientation for both large and small dimensions during stamping;

2. Positioning holes refer to the holes used in car body welding to locate automotive stamping parts. Due the requirement for precise orientation during car body welding, positioning holes are mostly circular holes, and there are also very few positioning holes that are planned as squares due to special requirements. This type of hole requires precise orientation for both large and small dimensions during stamping;

3. Processorum holas inter convenientiam accessorium, holas fluctus natantis fluctus in electrophoresis, gapes plantatae ad formandum et reducendum pessimum partium pulsavorum, et gapes, quae ad formabilitatem planantur. Processorum holas habent diversas formas, dimensiones, et orientationes, et in principio determinantur per propositum, formam, et proceduram pulsavi.

The requirement is to clarify that in the planning of automotive Metal Stamping parts, the above three types of holes are not independent of each other. For example, positioning holes can also serve as process holes, and process holes can also be used as positioning holes. Automotive stamping parts factories should be sensitive to the differences between these three types of holes based on actual situations. In special cases, the device hole can be used as a process hole, but generally can not be used as a positioning hole. A reason that positioning holes are mostly planned to grow holes, there will be significant errors when positioning them. Second, i the device hole will be welded with a cooperative specification component such as a protruding welding nut or a welding bolt before welding. If it is forcibly used as a positioning hole, a pin with a special shape that is difficult to process will be required on the fixture, and the positioning may not be accurate.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole