A five axis CNC Machining center is a CNC machine tool that integrates milling, precision milling, precision boring, drilling, and reaming, and can process various types of sheet metal, molds, and other small and medium sized hardware parts. Commone utili ad processendum componentes aerospace, sicut fuselage parts, impellers, blades, spirale grooves, et alias partes altas precision, et medica, inclined slots, slanted holes, et varias hardware parts curvatae.

Nullus est sequentibus conditionibus ad operationem normatis quinque instrumentorum machinarum CNC machinarum axis CNC: voltage energiae quinque instrumenti machinarum axis minor fluctuationem habet, temperatura ambiente inferior 30 C, et temperatura relativa inferior 80%.

1. Requirements for positioning environment of five axis CNC machining CNC machine tools

Orientatio machinae CNC quinque axis ab fonte oscillationis abissima est. Avoide rectam lucem solis et radiationem thermalem, et humilitatem et fluctum aeris. Si fuerit fontes oscillation is prope instrumentum machinae, anti vibrationis grooves circum instrumentum machinae constituentur. Otherwise, it will directly affect the accuracy and stability of the five axis linkage machining CNC machine tool, causing poor contact of electronic components, forming problems, and affecting the reliability of the machine tool.

2. Potentia Power for five axis machining CNC machine tools

Generally speaking, CNC lathes are installed in machine tools workshops, which not only have large temperature changes and poor operating conditions, but also various mechanical and electrical equipment can cause significant fluctuations in the power grid. Therefore, the installation orientation of the five axis CNC lathe requires strict control of the power supply voltage. fluctuatio voltationis energiae inter regionem pertinentem esse et relativi stabile manere debet. Otherwise, it will affect the normal operation of the CNC system.

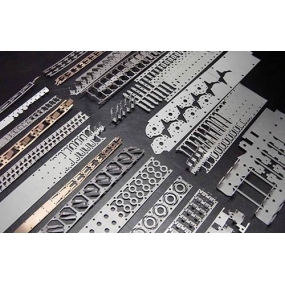

Stainless steel five axis machining

3. Conditions Temperatura quinque axis machining CNC machine tools

The environmental temperature of the CNC lathe is less than 30 degrees Celsius, and the relative temperature is less than 80 inches. Generally speaking, CNC electronic control boxes have exhaust fans or cooling fans to maintain the operating temperature of electronic components, especially when the CPU is constant or the temperature difference is not significant. Temperatura alta et humilitas potest animam servitutis componentium systemae constitui et frequencatem malfunctionum crescere. In augmento temperaturae et humilitatis, additione pulverem coniunctabitur cum circuitu integro, circuitu breve formans.

4. Uter instrumentum machinae quinque axis iuxta instruktiones

Productor non potest convertere parametros in system a controlli machinae CNC quinque axis quando utilizatur. The setting of these parameters is directly related to the dynamic characteristics of the machine tool. Nunc parametros corrigentiae interiora iuxta situationem actual adjustari potest. Et utentes non licet privati substituere accessories, sicut hydraulic chucks et instrumenta machinae, quae excedunt specificationes. In cunctis partes, fabricator perfecto considerit parametros conparantes unicuius ligaminis. Si arbitrarii substitui, parametros unius ligaminis inconsistentur, qui ad accidentes ducent.

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole