CNC Machining "style=" color: rgb (79, 129, 189); font-size: 24px; Quomodo ad machinas CNC quoteari

Cum extra processionem procedere, quotatio est gradus crucial, particular ad machinas CNC, ubi quotatio gravissima est. In CNC machining, there is a certain calculation formula for quotation. Haec formulae ad omnes adiuvare potest pretium CNC machinationis rationale computare.

CNC machining centers are mainly used for processing various types of small and medium-sized batch parts. Cum graduale diminuerit fabricationes CNC machinatorium centrorum, facti sunt etiam casa multarum parterum processi. Cum parvulos batches et singulos pecus productionem processerint, potest etiam currit tempus defectum programae et tempus preparation is instrumentorum.

CNC machining centers process parts with low surface roughness values. Gravitas superficie dependt on the cutting speed and feed rate when the material, precision machining allowance, and tool angle of the workpiece and tool are constant.

1, Product cost analysis

Quotante ad machinas CNC, primus gradus est difficile analisi productionis cost is. Datum precissimum pro quotatione providere.

1. Procedus interrogationis: Receive business, purchase new products - Inquiry - Understand content, confirm requirements - Seek suppliers - Check previous quotes for similar products - Manufacturer quotes - Confirm unit price for approval by supervisor - Respond to relevant units - Track and confirm unit price and other information - Feedback and report.

2. Valuatio procedura: Review the business evaluation report - Content analysis - Fill in the valuation details - Supervisor approval - Send the original to the business department - Track and confirm the quotation - The business will enter the confirmed original quotation details into the computer - Confirm the cost of each process.

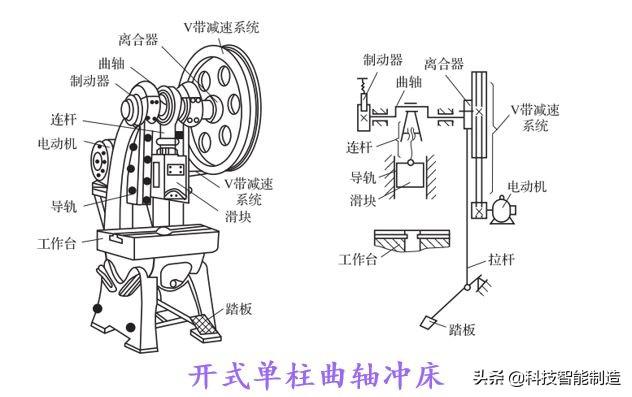

2, Planning standards for CNC machining machines

Prima standard calculi (quando tempor simulation is programmae minus est aut aequal 120 minutis)

Planned time=[Calculation of clamping measurement time+Heat up time+(Program simulation time * 1.7 times)] * Number of pieces

Secunda standard computationis (quando tempus simulation is programmae maior est quam 120 minutas)

Planned time=[Calculation of clamping measurement time+Heat up time+(Program simulation time * 1.5 times)] * Number of pieces

The clamping and measuring time (outside the program running time)=cleaning+clamping and calibration time in minutes+installation and disassembly of tool heads, tool copying+measurement+workpiece disassembly time

Note: Basis for measuring clamping time

Laboratorium: Tempus purificationis est 1-2 minuta per partem, et instauratio et auferetur caput succidentis manu omni minuta. Calibracionis caliperis mensus est 0,5 vices per minutam, et mensus wave mensus est unum numerum per minutam. Disassemble the workpiece for 1-5 minutes per piece.

Copper Gong: Tempus purificationis est etiam 1-2 minuta per partem. Mensa calibration is clampionis unum in minuta est. Use an automatic culter to disrupt the blade, with each blade being removed every minute. Mesura est aeque quam opus. Unum partem per minutam dissipate.

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole