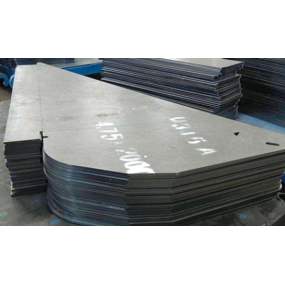

In process punching metallic stamping parts, a causa of certain factors, the material of the Metal Stamping parts may exhibit twisting and shrinking phenomena. So, how to improve the flatness of the metal stamping parts? Aspicamus subter:

Due the inherent internal stress of the sheet metal, metal stamping parts undergo elastic deformation during punching. The materials adjacent to the cutting edge first exhibit a downward bending arch of the sheet metal inside the cutting edge and an upward bending arch of the sheet metal outside the cutting edge. Worse still, this elastic bending arch cannot be completely restored, resulting in poor flatness of the metal stamping parts. When punching metal stamping parts, the situation where no pressing force is applied results in elastic bending during punching, not only at the edge of the dropped part, but also around the punched hole. So we need to choose other processes and configure other mold structures;

Si sufficienta elastic pressing force is applied to the upper and lower parts of the sheet metal during the punching of metal stamping parts, the elastic bending of the sheet metal will be greatly suppressed. Generally, the punching die uses an elastic discharge plate to press the material, but only for some metal stamping parts with low flatness requirements, because its effect is very small.

If some customers have requirements for the flatness of metal stamping parts, we can choose molds with elastic support blocks to improve the surface flatness of metal stamping parts.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole