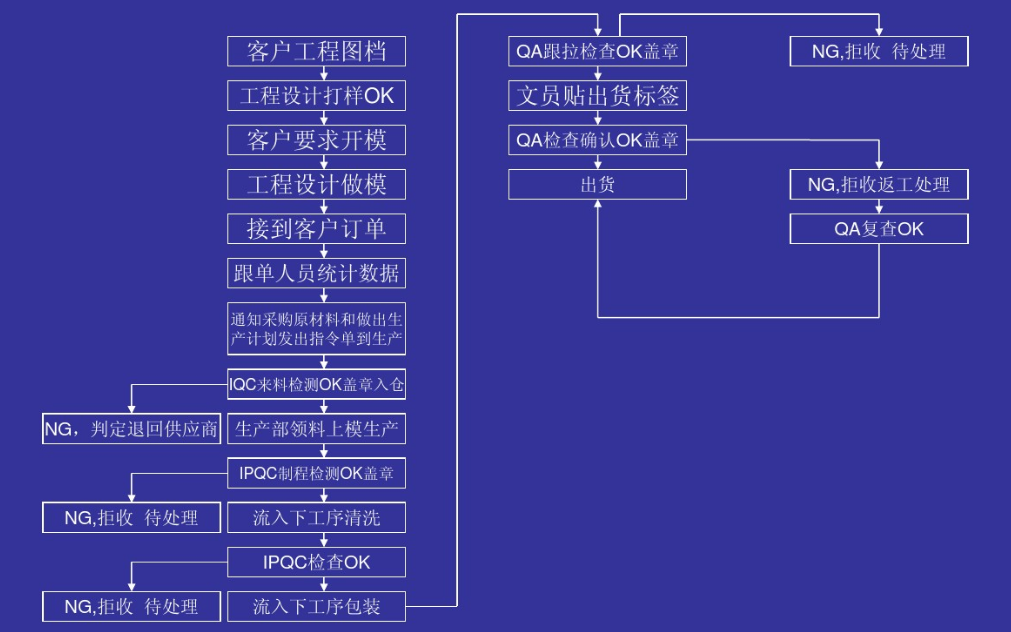

Taking Shenzhen Lida Precision Factory as an example, our production process generally consists of 16 steps, as shown in the following figure.

Prima opus nostra est:

1、 Production plan: The follow-up department shall promptly confirm the inventory status of raw materials, finished products, etc. in the factory after receiving the order; Indica si tabulata technica et lista materiae in loco sunt; Whether the materials can be timely, timely, and in place on time; Arrange the production plan and prepare a copy of the production instruction to be sent to the production department.

2、 Incoming inspection: To ensure the quality at the source, it is necessary to take a sample of about 1 meter from each roll of raw materials for the following inspection. By visually inspecting and verifying the sample, the material is checked for consistency, and the surface of the material is checked for oxidation, dirt, and other appearance defects. Use a micrometer to check whether the thickness and specifications of the material meet the standards; Each roll is sampled and subjected to reflow soldering to test the material's high temperature resistance (whether there are any defects such as deformation, color difference, oxidation, etc. on the surface after conducting high temperature testing)

3、 After receiving the production instruction form, the production department produces: materials are collected according to the requirements of the instruction form; Transferte materiam in molam, crescere et secere illum per plurimas pressiones, causantes materiam deformare in expectatione directo molae, et crescere opus. Prima parabola inspicetur et iudicabitur secundum omnes elementos inspectionis in libro guide inspectionis et primus parabolus parabolus parabolus est et confirmabitur antequam productionem coeperat. Procedentia fabricationis, cum machinam incipientis et autocontrolis regular is facientibus, necessaria est, si invenerunt defectus, machina confestim extinguetur pro meliora.

4,Washing water: At least two cleaning processes. Take the work in the area to be cleaned and load it in a mesh container. Then put it in an ultrasonic wave and clean it with carbon and hydrogen for 10 minutes to clean the surface oil stains of the workpiece. Post auferendum, pone illum in tanke hydrocarbon secundari mundationis et iterum quinque minutis purga ut omnem reliquum sexum super superficiem auferat. After taking it out again, place the workpiece in the cleaning tank for 3-5 minutes and filter out the hydrocarbons. During the cleaning process, replace the cleaning agent regularly every 3 hours to ensure the cleaning effect. Then spread the workpiece and place it on the air dry equipment for about 10 minutes to allow it to air completely dry. Afterwards, place the workpiece in the transfer box.

5,Packaging: Wear fingers covers throughout the packaging process and replace them in a timely way to avoid direct contact between the skin and the workpiece, and to prevent finger marks, dirt and poor oxidation. The workpieces in the packaging area shall be randomly inspected according to the inspection instructions, and can only be put into packaging after being confirmed to be correct and stamped. Pone peccatum opus packatum super mensam de packaging et pone illum in taberna tabulae in eadem directionem. Ante placationem illum, ipse proba si aliquid defectus apparuerit super superficiem opus. Post accuractem confirmationem, packager etiquetta interiora cista affixit et cista ad navigationem signavit.

6、 Confirmation before shipment: The clerk shall affix the shipping label, and QA shall confirm whether the material code on the shipping label is correct, whether it matches the actual product, and whether the quantity is correct. After confirmation, the shipping label must be stamped for confirmation before shipment can be made. If there are any abnormalities, timely rejection and problem feedback shall be made, and modifications and rework shall be made.

Emma Technology Co., Ltd. is one of the leading professional manufacturers of precision metal parts in China, established in 2006. It mainly undertakes business such as CNC Machining parts, metal stamping parts, and sheet metal processing.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque