Haec experientia prima est principibus principibus discentibus videre et exercere. Quia nemo online de his scribit, sed haec basia vere gravissima sunt.

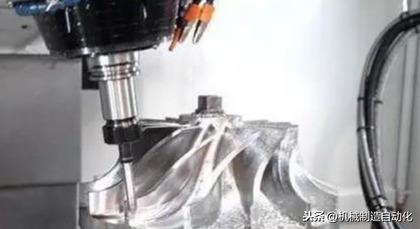

CNC Machining process

1. Accept the material~Check if the length, width, height, material and serial number of the material match the drawing to be processed

2 clamps~Attention a placement of the workpiece, is it placed the same as the drawing? Is it clamped? numquid Mae Zai et Pi-si in medio graduum et superabunt Num cultrum percutiet?

3. Rough machining within 0.03mm and precision machining within 0.01mm.

4 puncti in medio~Find the benchmark position and check it again in the middle. Retreat 5mm for the larger end and 2mm for the smaller end.

Cumque cultri in drawingibus convenerunt, observate cultros, videte quod longitudo machinae sufficiat, et si cultros colligent.

Arrangement of CNC machining center sequence

Generally speaking, the arrangement of processing sequence should be considered based on the structure and condition of the parts, as well as the need for positioning and clamping, with a focus on ensuring that the rigidity of the workpiece is not compromised. Ordine sequitur sequentibus principibus generalmente:

1. The CNC machining of the previous process should not affect the positioning and clamping of the next process, and if there are universal machining processes interspersed in the middle, comprehensive consideration should also be given.

2. Primo procedere inter speluncam machinaturam, et postea procedere machinaturam exteriorem.

3. Melius est connectare manum CNC cum eadem positionem, methodo clampionis aut id ipsum instrumentum ut reduceret numerum repetitionis positionis, instrumentorum mutationis, et pulsationem pressionis.

4. For multiple processes carried out in the same installation, the process with minimal rigid damage to the workpiece should be arranged first.

Quod aspectus attention debet quando foedus clampionis opus determinare?

Definientes referentiam positionis et clampionis schemas sequentes tres punctos notabuntur:

1. Strive for consistency in design, process and programming calculations.

2. Proba minimizare numerum temporum clampionis et conplere CNC machinationem omnium superficium machinari post unum positionem.

3. Avoide manum adjustationem planas quae machinam occupant.

4. The fixture should be open and its positioning and clamping mechanism should not affect the tool path in CNC machining (such as collision). When encountering such situations, it can be clamped using pliers or adding bottom plate screws.

The machining process, as well as the clamping and positioning standards of the workpiece, may seem ordinary but are actually the first step in efficient production. Strict control at the source is the key to high-quality products.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque