In recent years, with the rapid development of the sheet processing industry, more and more enterprises have chosen to customize Sheet Metal Processing on monitoring workstations. Consolio monitoring a est speciosa speciosa workstation utilis pro installatione et operatio systemarum monitoringum, cum functione...

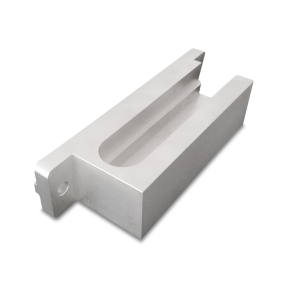

In recent years, with the rapid development of the sheet processing industry, more and more enterprises have chosen to customize sheet metal processing on monitoring workstations. Consolus monitorins est speciosus speciosus workstation ut installatur et operatur systemae monitorins et functiones eius et design propter speciosas necessitates customizatur. In order to help everyone better understand and master the customized process flow and material selection of sheet metal processing, we will provide a detailed introduction below. First, let's understand the process flow of sheet metal processing customization. The customized process flow for sheet metal processing includes the following steps: 1. Requirement confirmation: Determine the specific requirements for monitoring the operation platform, such as size, shape, function, etc. 2. Design plan: Based on the confirmed requirements, design a monitoring console plan that meets the requirements. In schema design, necesse est considere arrangement of the monitoring system, the materials used for the operating platform, and the structure inside the lower cabinet. 3. Material selection: Select suitable materials for production according to the design scheme. Materiae usus frigidae lapides, lapides sterilis, etc., et electiones eorum stabilitatem et corrosionem resistentiam opus considerare debent. 4. Processum et productionem: Processum et productum secundum schemam design et electionem material. Procedus processionis et fabricationis inter proceduras, quales sectionis, bending, and welding. 5. Trepta superficie: Post processionem, necesse est facie tractionis superficie in consolo supervisoris ut meliorem apparentiam et durabilitatem eius. Common surface treatment methods include spraying, galvanizing, etc. 6. Assembly and installation: Assemble each component and proceed with installation. During the assembly and installation process, attention should be paid to the accuracy of each component and the rationality of the installation position. In addition to the process flow, material selection is also a key link in sheet metal processing customization. Elegantibus materiae, sequentibus factoribus considerari sunt: 1. Fortitudo et duritate: Consolio supervisoris sufficit fortitudinem et duritatem habere, ut stabilitatem et durabilitatem suam assegurat. 2. Resistentia corozionis: Quia saepe in humilio medio supervisoris est, oportet elegere materiales cum bono corrosione resistentia, ut prohibiret rustum et oxidationem. 3. Conductivity: The monitoring console needs to have good conductivity to ensure smooth and unobstructed current and signal transmission between various components. 4. Costa: Quando materiales elegit, factores costis etiam considere sunt, ut economiam lapides facientem personalizationem metallorum. In summario, the process flow and material selection of sheet metal processing customization are important links in the production of monitoring operations platforms. Solmente per fluxum procedentis et elegit adequatos materiales qualitatem et functionem consoli monitorins garantia potest. I hope the above content is helpful for everyone to understand and master sheet metal processing customization!

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque