Fondatio est fundamentum essentiam fabricatione lapides plasticas, et tantum per mold a fabricationem vacuum fabricabitur.

Si mollus non bene facit, significat, quod postea producentia plastica "longa" et pulssa sunt.

Aliquis interrogavit: Quid mold bonus est vacuum packaging production? So, Nobel will explain to you:

What are the main categories of vacuum packaging production molds?

conflationes in ligna divisae sunt, conflationes gypsum, conflationes aereas et conflationes aluminium.

1. Fabrica ligna: Fabrica ex ligno substituo et processa per maquinam carvinum est. Minus costum et velocitatem aperientiae velocitatem habet, et generale in fabulis pallium vacuum utilitur. Sed, transparentia exemplorum non alta est, et mollus pronus ad deformationem est.

Wooden mold

2. Gypsum mold: The advantage is that the production cycle is short, the cost is low, and it only takes one to two days to make a complete (60110cm) mold; The shortcomings lie in the hard surface of the vacuum molded product, the easy breakage of the mold during production, poor durability, and the inability to form products with large depth, high complexity, and thick sheet materials.

Aedificatione gypsum fertur gypsum in semi humida state et deinceps siccantur ut formaret molam.

Gypsum mold

3. Copper mold: The process of electroplating copper mold is to spray a layer of conductive agent on the surface of the pre made bubble shell, and then put it into an electrolytic cell to deposit a thick copper layer. The electroplating process takes 72 hours, and then the copper mold needs to be filled with gypsum. The purpose of filling gypsum is to increase hardness, followed by polishing and air hole treatment.

Produktio fabricationis fusilium electroplatorum est moderata et robustum durabilitatem habent. Superficie vacuum fabricatorum producentium cum eis relativamente planctum erit, sed propter longum produktio ciklum, produktio vacuum fabricatorum precision is non potest impleti.

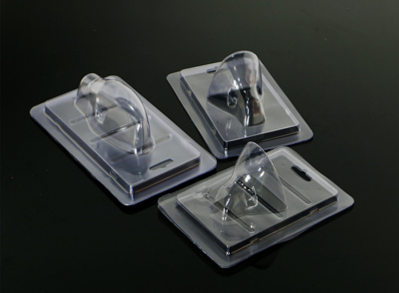

Non curved samples of copper/gypsum molds

4. Aluminum mold: Aluminum mold production is made using computer design drawings and CNC milling machines. Its production cycle is moderate, and the later mold processing time is short. Its drilling air hole work needs to be completed during CNC processing. Its durability is strong, and the size accuracy of the vacuum molded products produced with it is high, but the cost is relatively high.

Exempli ex mollis aluminium facti

Finally, in terms of price, aluminum molds> Mellens coper; ligna fabrica; Gypsum molatus est.

Gypsum molds are usually used to make samples for customers, but their characteristics determine that they cannot be used as mass production molds.

For vacuum packaging with low requirements for curves, molds of copper can be used.

Aluminium molda optima est pro productione vacuum molding magna et alta demand, cum avantias, quasi durabilitate, alta efficientia, et extremely low velocitate scrap.

Machina plastica/machina vacuum packaging machine

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque