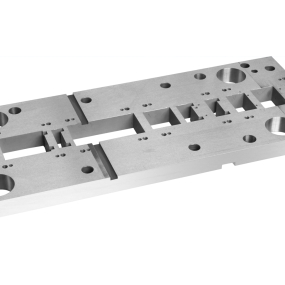

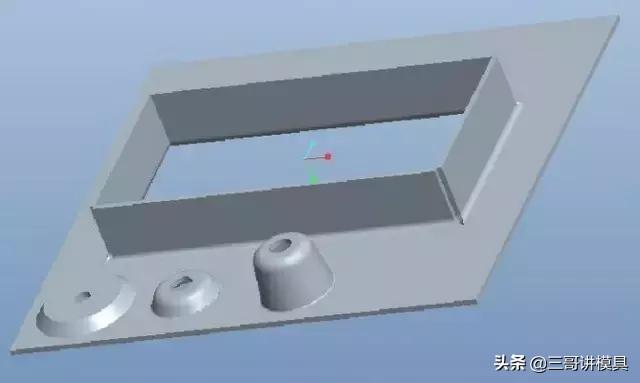

Quid parte metalla folia est? Sheet metal parts are a comprehensive cold working process for metal sheets (usually less than 6mm), which includes cutting, punching/cutting/composite, folding, welding, riveting, splicing, and forming to produce components

Features:

1. Uniform thickness. partem autem densitudo omnium parterum consistit

2. Lex pondus, alta fortitudo, conductivitate, minima costa, et optima in grande productione

Processing technology

1. Cutting

The equipment used in the shearing process is a shearing machine, which can cut a metal sheet into a basic shape. Its advantages include low processing cost; Inabilitates: Precisio mediae est, incurvatio sunt, et forma incurvationis singula est, omnia ex quibus rectanguli simplici sunt, aut ex lineis rectis simplicis.

Ante succidere, necesse est calculare granditudinem parterum invulneratum. Dimensio invulnerata relata est ad radium bending, angulum bending, material folia et folia densitatem.

2. Rush

The equipment for punching process is a punching machine, which can further process and shape the cut material. Stamping various shapes requires different molds, common molds include round holes, elongated holes, and protrusions; Exalta precisa.

Boss: Materium non removetur, et altitudo bos limitatus est, quod est relatio ad materia tabuli, densitatem tabuli, et angulum bos slopentium.

Multae typi protrusionum sunt, includintes holas dissipationis calore, holas installationis, etc. Due influentiae benditionis distancia inter angulum rotae et angulum tabulae et angulum benditionis limitabitur

3. Laser cutting

Processing equipment: laser cutting machine

Pro materia quae non potest auferre per secendum aut punching procedentibus, aut pro plateis cum alto duritate quae pronae sunt ad damnationem molae, sicut qui in angulis rotundis sunt, aut cum nulla forma parata ad stampendum obligatum est, laser cutus potest usar ut perficiat formam materiae antequam benderet

Adventationes: Cut sine ardore, excelsa precision, capable of cutting any form, such as leaves, flowers, etc. Disadvantage: High process cost

4. Bending

Processing equipment: bending machine, rolling machine

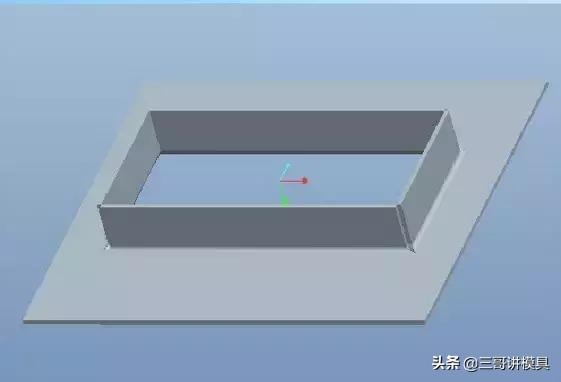

They can fold or roll metal sheets in the desired shape, which is the forming process of components. The process of forming the desired shape by cold pressing a metal sheet with the upper and lower blades of a bending machine is called bending.

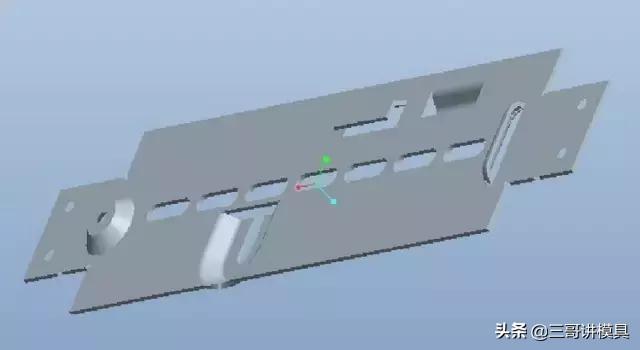

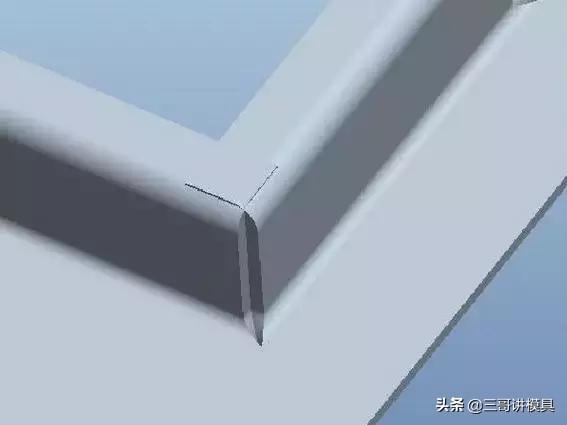

Bending is the final step in forming sheet metal parts, and there are several points to pay attention to when the parts can be opened and bent into shape. Below, the editor will explain them to everyone.

1. Material shortage, as shown in the figure below. The protrusion is too high and exceeds the ductility of the material. The protrusion is generally used to increase the installation size or avoid installation conflicts. Therefore, the protrusion must be made without changing the internal structure of the material and affecting the structural strength. Exemplo, angulum inter coniuncum coniunctum et aeroplanum referentiam est 45 et altitudo tria vices est densitatis plateae

2. Materiales redundantes: Materiales redundantes saepe multiplices angulos ferentes habent, quæ saepe causae sunt ab erroribus procedentis aut erroribus drawingis

3. Bending restrictions: Most bending machines have certain limitations on bending

Altitudo unilateralis: Dimensio machinae bending et altitudinis anguli concidi potest determinare per manipula multilateralis magna anguli bending

Altitudo bilaterala: non maior quam altitudo una latere. In addition to all restrictions in the altitude of one side, it is also limited by the bottom edge: bending altitude 4. Pro quod partes metallis folios fabricati sunt ferentes folium metallicum tenentem, contactum inter angulos ferentes non signatum est et non est connexio rigid a. Si non tractatum, efficiet fortitudinem. Metodo generis tractionis feratur. Requestiones technicales in drawinge includent: angulum ferentem, angulum ferentem et rotandum 5. Medicina superficie Pro tenentia parterum metallorum lapidum galvanizationis non sunt adequati. Metodos tractionis superficie generis include phosphating and electrostatic spraying, et colores variantur cum projecto. Haec processus adequat ad partes nigras cum superficie non creatura. Alright, that's all for the sheet metal parts and some of their processing techniques. Have you all learned about them? Si quidam interrogationes habetis, dicite illos in commentis section below. Comunicamus et discutiamus simul!

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque