Velisne miratus a fabricatione tunicae Zhangqiu ferreae in "Tongue 3", ubi centum aut etiam milia flammarum ferreae fragmenti rubri et fortes faciunt. Scisne quoniam paneli alae qui duos alas in magnis avionibus quae saepe navimus et similis technicis processionis fabricati sunt.

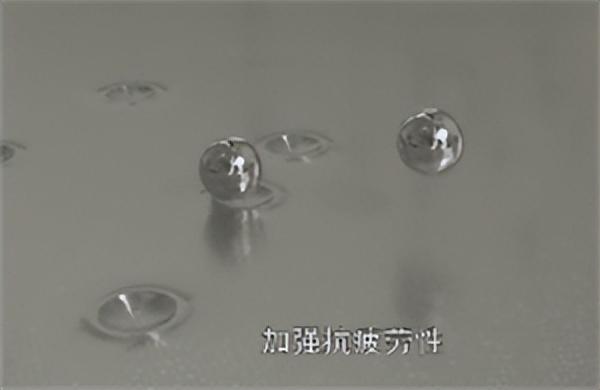

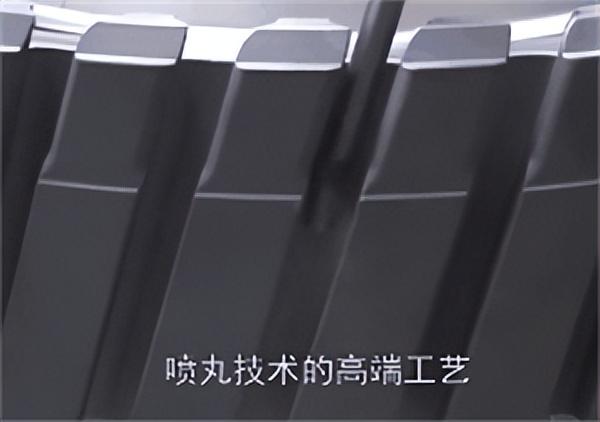

Of course, this high-end process, known as "shot peening technology," is much more complex than the production techniques of Zhangqiu iron pots. Utraque proprietatem communam est ut effectum fatigum resistentiam et magnificaret fortitudinem per effectum velociter. Differens est, quod malleus parvus projectilis factus est cum diametro non plus quam centimetro, et metallus ferrum factus est pretiosius materio crudelis. Produktum finitum est magnum parietem parietem parietem magnam habentem magnam fortitudinem et fortitudinem et formam multam complexam.

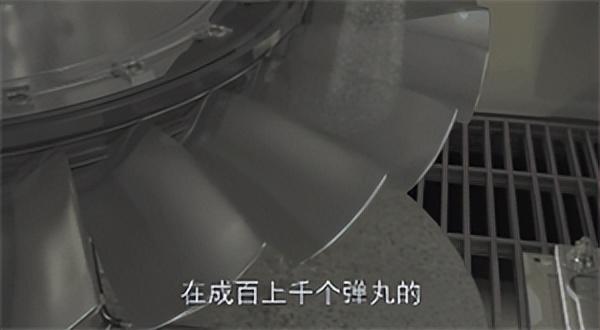

Such thick alloy raw materials, under the high-frequency and high-speed impact of hundreds or thousands of projectiles, become hard, complex in shape, and very thin skin. Finally, they are combined with the skeleton to form a complete wing, supporting the aircraft to fly at an altitude of tens of thousands of meters. Nonne hoc mirabile est?

Cur ergo tecnologiam piscationis utilimus ut paneles wing procedemur? First, we need to understand the special component of aircraft wing panels.

Aeroplane alak tipik tene-walled structure, mainly composed of skin and skeleton. Si aeroplanum similaremus avii, pelle similis plumis est, circum skeletum aeroplani, facientem faciem exteriorem fluctum. Formum vultum habere debet ut resistentiam reducatur; Debet esse multo lux et tenens, attingens decem aut etiam paucos milimetros, ut efficientem pondus portare et aeroplanam altior levare. It must also be very resilient to withstand the various maneuvers and twists made by the aircraft at high altitudes.

Traditional machining of wing wall panels usually uses CNC integral milling and appropriate mechanical bending methods. Solving the complex shape of the overall wall panel will waste a large amount of material, and mechanical bending can easily affect the performance of the wall panel, making quality control difficult. Nowadays, both domestic and foreign aviation manufacturing companies use shot peening technology for wing wall panel processing.

Unus est paululum costum, non est necessarium mollis, salvum raw materiales, et minus spatio occupant.

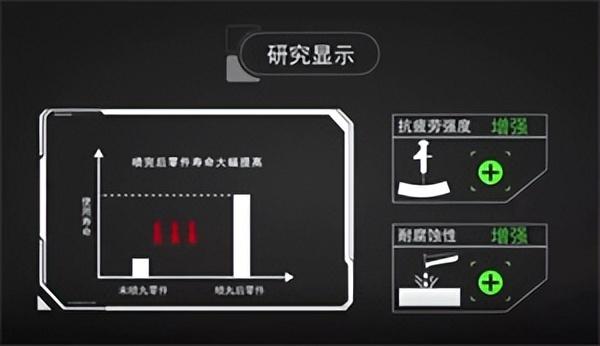

Secunda qualitate alta est, quae semper "percutit" faciem parterum densior fieri, sicut addit pelliculam protectilem partes.

Thirdly, it has a wide range of applications. No matter how complex the shape is, under computer programs, small projectiles can accurately locate and strike, effectively solving problems such as metal part processing deformation and welding part deformation.

Vita fatigae parterum processae per pinguinem a dozena temporibus in comparatione originalis potest crescere, et fortitudo fatigae et resistentia corrosionis multo elevata sunt.

Medium pro pictura est saepe dicitur quasi materia fusilae, et sunt multi typi, includientes fusionem steellam, fusionem steellam carburizatum, fusionem steellam difficilem, fusionem ceramicam et cetera. In field of aircraft manufacturing, shot peening generally uses carburized steel shot and hard cast steel shot, while shot peening strengthening technology mainly uses hard cast steel shot and ceramic shot.

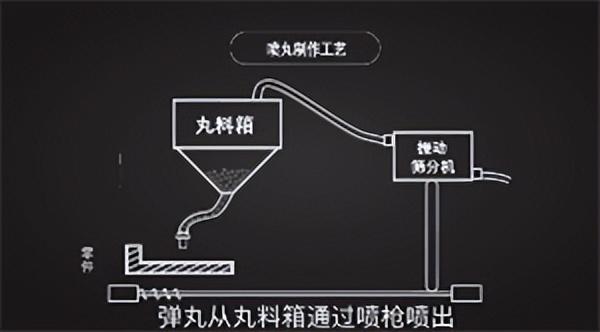

Procedus piscinae valde interessant est. In arma specializata procedentia, bullets are ejected from the shot material box through a spray gun, hitting the surface of the parts at high speed. Then, through a recycling system, unqualified bullets are screened out by a screening device and returned to the shot material box for re-use.

In order to give domestically produced aircraft stronger and lighter wings, Chinese aviation industry technology personnel are still working hard. More advanced technologies such as prestressed shot peening, ultrasonic shot peening, high-pressure water shot peening, and laser shock shot peening are bound to play a greater role in the near future.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque