Automobiles et instrumenti multo importantes rolos in diversis industriis orbis mundi, subito in industria automobilis. It is said that more than half of all gears produced around the world are aimed at the automotive industry.

Magnum numerum instrumentorum inter unidades principales transmissionis, differentiae, controlo et cetera utilizatur.

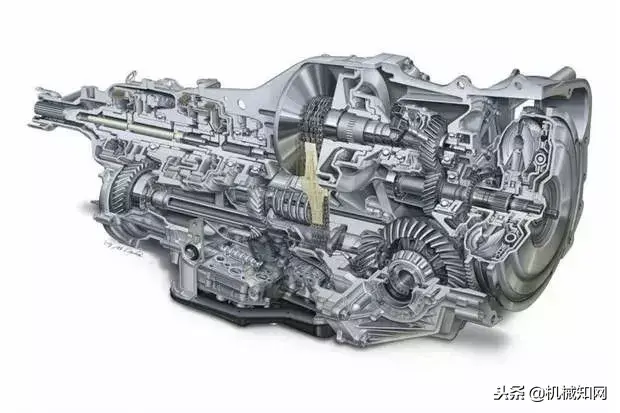

Applicationes Gear in automobilis

In order to reduce fuel consumption, multi-level transmission is being promoted with a focus on large vehicles. Multae instrumenti sunt instalii in multipolo fertilibus, et propter tendenciam ut cresceret sonitum, cum reduxerit fertilibus, etiam necesse est meliorare machinationem accuracionem et rectitudinem superficie dentum.

Problema sonitum reductionis per instrumenta non solum est pro motoribus gasolinis et diesel is, sed etiam hybridis et electricas vehiculis, qui utilizant mechanismos gearis in driving parte.

Complex transmission structure

compound machining machine drives the evolution process of gear machining

compound machining machine drives the evolution process of gear machining

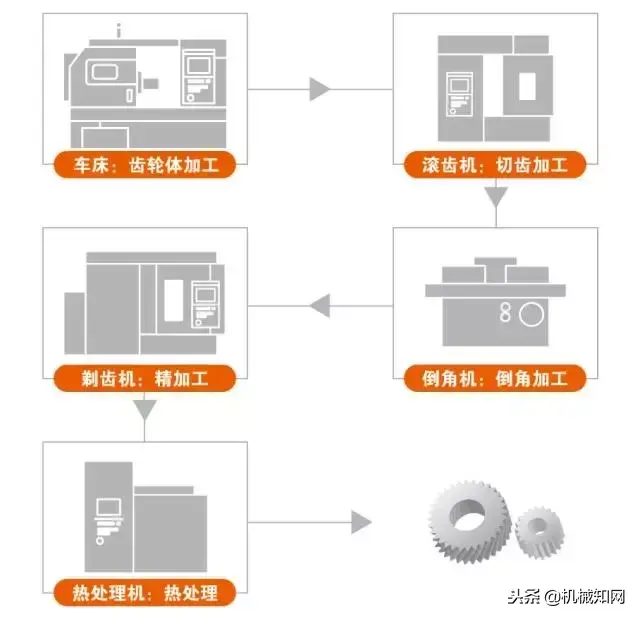

In fabricatione vestimentorum spurorum, praecessima operatio germinatorum cum manipulatione corporis vestimentorum in lathe coepit, secundum germinatorum hobbing machinae hobbing, chamfering cum machina cubicularum, et machina precision cum machina rassionis vestimentis antequam calefactorum conplerentur.

The production lines made from these specialized machinery have many advantages in large-scale production, but they are not very suitable for multi variety and small quantity production. In recent years, there has been a trend to transfer production to production lines using general machines such as composite processing machines.

Previous gear machining methods

Cum machina composita ad machinas gear machinas utilizat, utilitates CNC lathes et machinas centros utilizatur. Previously, gear cutting and precision machining were carried out using multiple specialized machines, and all machining processes until heat treatment could be completed using one machine.

Compared with previous production methods, when producing multiple varieties and a small quantity, process intensification can shorten processing time, reduce the number of equipment and machines, and improve processing accuracy.

The gear processing application program for "smooth milling," "smooth hobbing," and "smooth turning" using a composite machining machine completes all processes from basic machining to precision machining of gears through a single clamping process. Especially when processing small batches of gears and large-diameter gears, the production efficiency can be greatly improved.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque