With the increasing popularity of metal body smartphones, words related to metal body processing technology such as CNC, stamping, forging, die-casting, and so on have become more and more frequent. Below is a detailed introduction to several commonly used processing methods for metal body in mobile phones.

1. Casting

Metal casting is the process of injecting molten metal in a hollow mold made of high temperature resistant materials, condensing it to obtain the desired shape of the product, and the resulting product is the casting.

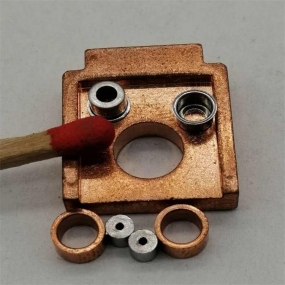

Casting metallis in gravitate casting et pressure casting based on whether it is affected by pressure. Gravitas casting refert to the process of injecting molten metal into a mold under the influence of the Earth's gravity, also known as casting; liquidum metallicum generale effundetur manum in portam, reliquum est super se pessimum liquidi metallici ut impleret cavernam fusilam, exhaustam, frigidam, et aperire molam ut productum acciperet. Pressure casting refert to the method of filling the cavity of a die casting molted with liquid or semi liquid metal at a high speed under high pressure, and forming and solidifying under pressure to obtain castings. Metal Meilan released by Meizu adopt high-pressure casting followed by spray coating treatment.

Meilan Metal

2. Forgetting

Forging refers to a machining process that uses pressure to change the shape of metal raw materials in order to obtain forgings with certain mechanical properties, shape, and size.

Metal forging can be divided into five types based on the different tools used for pressurization: hammer forging, drop hammer forging, pressure forging, end pressure forging, and rolling forging. Hammer pressing refert to heating the work piece to forging temperature and forging it between a flat hammer and a drilling plate; Parva partes manu ferro vocabitur Large items require the use of a steam hammer. The difference between drop hammer forging and flat forging lies in the fact that the hammer in drop hammer forging has a die cavity, in which the work piece bears two types of pressure or impact forces, and then undergoes plastic deformation according to the shape of the die cavity. Pressure forging is a forging method that uses slow pressure to squeeze metal into shape in the mold. Due to the long time the metal is subjected to force, the squeezing effect not only occurs on the surface of the forging, but also on the central part of the workpiece, achieving a uniform effect inside and outside. For example, the R7 mobile phone case of OPPO is made by pressure forging followed by surface anodizing treatment.

OPPO r7

Punching

Stamping refert to the direct force forming of metal sheets in a mold using the power of stamping equipment. It is a cold treatment method, also known as cold stamping or sheet metal stamping. Fluxus procedentis in tres gradus subdivisus potest: primum, fixer plateam metallam super mensam molam, tunc punch superior verticali cadit ut format plateam metallam sub fortitudine intra molam, et finem punch ascendet. Partibus extracti sunt et expectant proximum terminum trimming et pulsationis. Totum processum accipit circa 1s-1min. Xiaomi's Redmi Note 3 is a metal back cover made using stamping technology.

color

paper size Processus CNC

CNC, Nomen kompletus est Control Computer Numerical, quod referit ad instrumentum automatum machinae controllum a programma, saepe notum est "instrumentum machinae CNC". This control system is capable of logically processing programs with control codes or other symbolic instructions. Through computer decoding, the machine tool executes predetermined actions, and through long-term precision machining, a raw metal sheet is ultimately shaped into the desired shape. Starting from the iPhone 5, Apple has adopted aluminum alloy integrated molding, with the body and frame made of a single piece of aluminum alloy CNC Machining.

iPhone 6

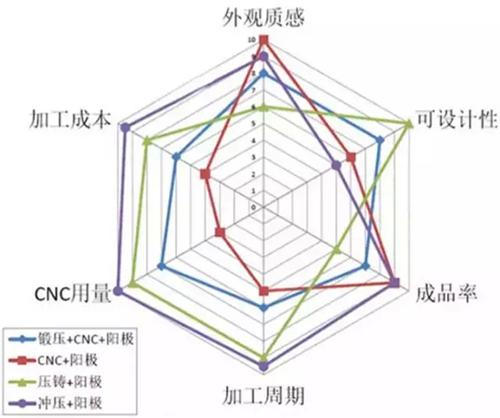

Quod modus technologiae processionis pro metallo casing telephonorum et illius processionis pretium est Quantitas CNC utilis, processationis ciklus, generatio, designabilitate et apparentiae texturae closer relatae sunt, et haec influentiae factores poterunt diagramma radar procedentibus form are. Quanto maximus est diagramma radar procedentis, melior est omnis exercitus eius; Ex universa mensura analisi, omnis dimension in decem nivellos dividitur, et maximus punctus, melior est processus in illa dimensione.

Radiographica

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque