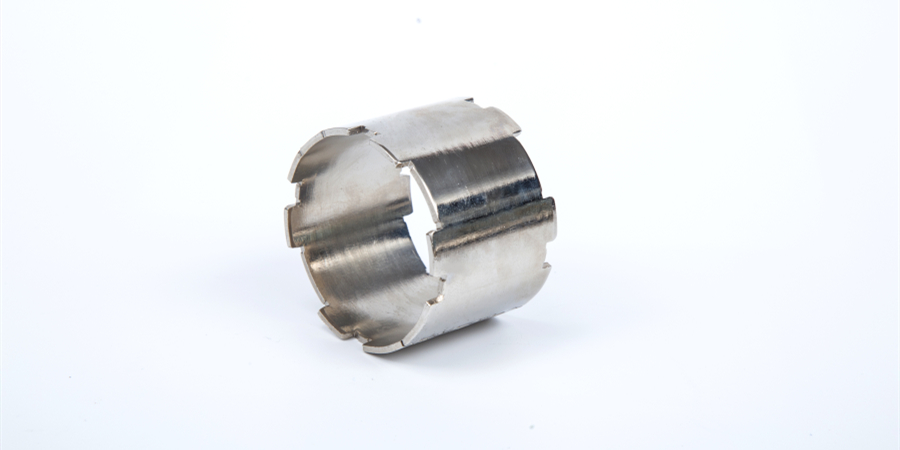

A punch press is a stamping type press machine. In production, the stamping process has the power to save materials compared to traditional mechanical processing, and has high efficiency. It also does not require high operator skills and can produce products that cannot be reached by mechanical processing through various mold applications. Therefore, its use in stamping factories is becoming increasingly widespread. Punching machines are widely used in electronics, communications, computers, household appliances, furniture, transportation, hardware components, and other stamping and forming industries.

Punching machines play a lot in hardware equipment processing:

1. Punching, thick sheet punching, and punching production are mainly aimed at sheet metal. They can pass through molds, make cutting, punching, forming, deep drawing, trimming, precision punching, shaping, riveting, and extrusion parts utt. They can process parts with large scales and complex shapes. Five metal printing has high strength and rigidity.

2. Izveidojot tādas kā dzelzs plāksnes, krāsas, kabīnes, plāksnes utt., ir nepieciešams mazāk materiāla patēriņa metāla zīmogu pārstrādei iespiešanas rūpnīcās, kā arī metāla zīmogu daļu izmaksas ir salīdzinoši zemas.

3. Trimming and shaping can be applied to uneven metal surfaces. During Metal Stamping, the mold ensures the stability of the scale, shape accuracy, and quality of the metal stamping parts.

4. Putnē, savienojot divus metāla objektus kopā, patērē mazāk materiālu un nepieprasa citas siltumapgādes iekārtas. Tā ir arī materiāla ietaupīšanas un enerģijas ietaupīšanas pārstrādes metode. Metāla iespiešanas daļu izmaksas ir zemas, padarot to piemērotu lielapjoma ražošanai un piemērošanai.

Šis pants ir no EMAR Mold Co., Ltd. Plašāka informācija par EMAR, lūdzu, nospiediet www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque