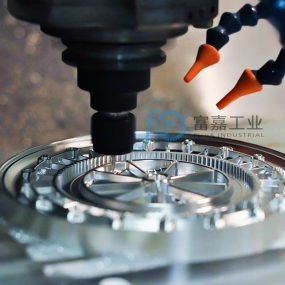

Bħalissa, aktar u aktar intrapriżi qed jużaw ħiliet ta’ makkinarju tas-CNC f’ħames assi, minħabba li l-iżvilupp ta’ ħiliet ta’ ħames assi huwa matur ħafna u ġie applikat b’mod wiesa’ u għandu rwol importanti fl-ajruspazju, il-karozzi, it-tagħmir mediku, l-oqsma militari u oqsma oħra. Jista’ jingħad li l-makkinarju tas-CNC b’ħames assi huwa ħila eċċellenti tal-makkinarju tas-CNC, u għandu l-vantaġġi ta’ preċiżjoni għolja tal-makkinarju, qawwa għolja tal-produzzjoni, u inqas spejjeż tal-produzzjoni.

In the future society, with the advancement of industrial automation and the development of intelligent manufacturing, five axis CNC Machining will be more widely used in industrial production. Especially in the aerospace industry, five axis CNC machining skills have become a standard for producing high-precision aerospace components, as these components require working in complex environments such as high and low temperatures, low air pressure, and high precision, and reliable quality. Five axis CNC machining can not only meet these requirements, but also significantly reduce production costs and improve production power.

In the field of sedan manufacturing, five axis CNC machining is primarily used to produce high-precision sedan components, such as engine cylinder blocks, wheel axles, crankshafts, and irregular curved parts. These components require high precision, and five axis CNC machining can ensure the accuracy of the parts, reduce the number of processing times, improve production power, and reduce production costs.

In addition, five axis CNC machining can also be applied to other professions. For example, in the field of medical equipment manufacturing, five axis CNC machining can produce high-precision medical equipment components, such as surgical instruments, prosthetic parts, etc. These devices require precision and quality assurance, and five axis CNC machining skills can meet these requirements while reducing production time and costs.

Overall, five axis CNC machining skills have many advantages and will have a wider range of application prospects in future industrial development. Skill upgrading and continuous improvement have become important directions for the future manufacturing industry, and five axis CNC machining skills will be one of the key skills for the transformation and upgrading of the manufacturing industry, injecting new momentum into its development.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque