A punch press is a stamping type press machine. In production, the stamping process has the power to save materials compared to traditional mechanical processing, and has high efficiency. It also does not require high operator skills and can produce products that cannot be reached by mechanical processing through various mold applications. Therefore, its use in stamping factories is becoming increasingly widespread. Punching machines are widely used in electronics, communications, computers, household appliances, furniture, transportation, hardware components, and other stamping and forming industries.

Punching machines play many roles in hardware equipment processing:

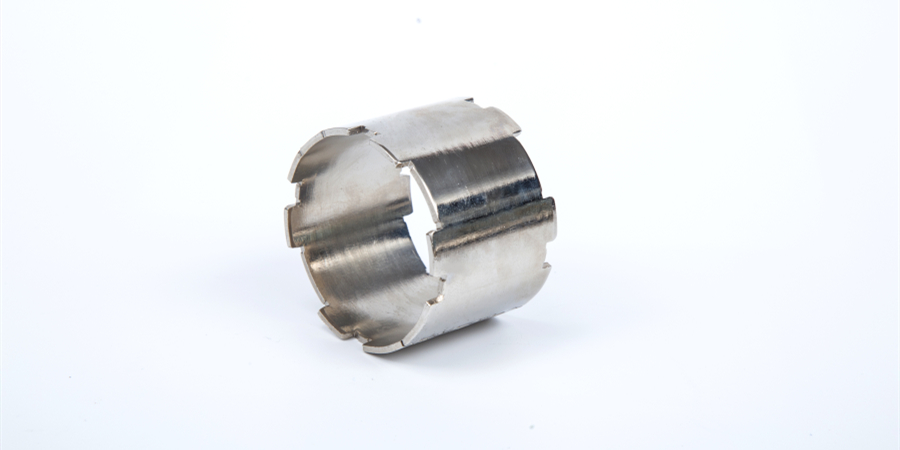

1. Punching, thick sheet punching, and punching production are mainly aimed at sheet metal. They can pass through molds, cut, punching, forming, deep drawing, trimming, precision punching, shaping, riveting, and extrusion parts etc. They can process parts with large scales and complex shapes. Five Metal Stamping has high strength and rigidity.

2. Forming, such as iron plates, cups, cabinets, plates, etc., requires less material consumption for metal stamping processing in stamping factories, and the cost of metal stamping parts is also relatively low.

3. ٹریمینگ اور ساپینگ نابرابر فلز سطح پر لازم کر سکتے ہیں. فلز استمپ کے موقع میں پھل کی مضبوطی کا ثابت قدم رکھتا ہے، شکل دقیق اور فلز استمپ کے ٹکڑوں کی کیفیت.

4. روئیٹینگ، دو متل objectوں کو ایک ساتھ اتصال کرنا، کم مواد صرف کرتا ہے اور دوسرے گرم وسائل کی ضرورت نہیں ہے. یہ بھی ایک مواد نجات اور انرژی ذخیره پردازی طریقہ ہے. متل سٹمپ ٹیمپ ٹیمپ ٹیمپ ٹیمپ ٹیمپ ٹیمپ کے قیمت کم ہے، اس کو بڑی اسکیل کے پیدا اور

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque