With the development of technology, there are more and more types of gold crafts on the market, including 3D hard gold, 5G gold, and ancient gold Wait, it's often confusing to distinguish. Today, let's take a look at 3D, 5D, 5G, and ancient methods together CNC、 Dot gold drill, low-temperature enamel, high-temperature blue burning process After reading it, you will know how to choose!

3D hard gold

1. The weight of 3D hard gold for jewelry of the same volume is approximately one-third of that of traditional foot gold, and its hardness is four times that of traditional foot gold;

2. Correspondingly, with the same volume, 3D hard gold is lighter in weight and more cost-effective than traditional full gold;

3. Due to its high hardness, 3D gold can have a stronger three-dimensional effect than regular gold;

4. 3D hard gold is pure gold, with the same gold content as regular gold.

5. The 3D hard gold has a hollow design, and the product itself is thin, so collision and compression should be avoided. It is recommended to remove it during daily bathing and sleeping to avoid bumping.

5D Hard Gold (can be understood as an upgraded version of 3D Hard Gold)

1. 5D hard gold is essentially the same as 3D hard gold, with only an upgrade in the field of electroforming;

2. The upgraded solution does not contain cyanide, commonly known as cyanide free 5D;

3. Upgrading the potion can increase the hardness of gold, make it thinner, and make it much lighter than traditional gold jewelry;

4. It is lighter, harder, brighter, more wear-resistant, and more environmentally friendly than 3D hard gold, and endows gold with higher wear resistance.

5G Gold

5G gold is an innovation in a new gold technology, which combines traditional gold and K-gold technologies. While ensuring the standard color of pure gold, it has higher hardness and ductility, which can break the limitations of traditional gold technology and achieve multiple design styles, making it more fashionable.

The production of 5G gold involves adding a certain amount of rare elements, commonly known as "hard gold powder", to the gold material during the process of dissolving gold, and then catalyzing it through high-temperature melting to make the molecular structure of gold more compact without affecting its purity.

Ancient Method Gold

Ancient gold is made using the ancient gold casting process of national intangible cultural heritage. It has the characteristics of being resistant to dirt and wear, difficult to leave fingerprints and sweat marks, less prone to scratches, and is suitable for playing with; And it is made of dense gold, which can showcase its heavy weight and texture both visually and when worn.

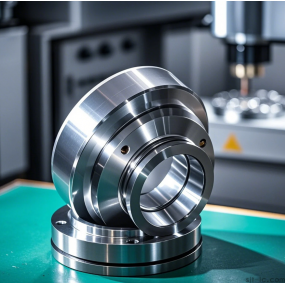

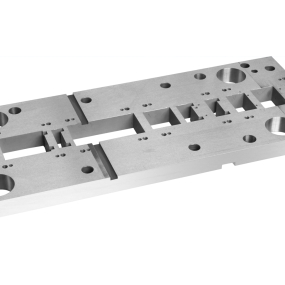

CNC Gold

CNC gold, in layman's terms, refers to gold jewelry that is cut by machines. Its full name is CNC computer digital control precision mechanical processing. All jewelry sizes and specifications are input into the computer for strict standard cutting, ensuring the consistency of product texture, high precision, good symmetry, and stable quality. These are the unique attributes and characteristics of CNC gold

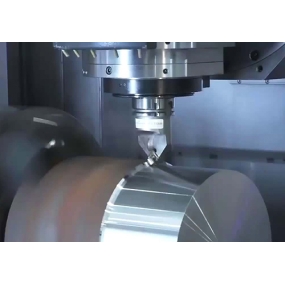

Dot Gold Dot Diamond

The new pure gold craftsmanship makes gold shine like a diamond.

The gold dot diamond technology is an innovative product that combines gold materials and CNC technology in the traditional gold field. This design retains the value preservation properties of gold while showcasing the brilliance of diamonds.

Using precision CNC technology to carve gold into diamond like facets, the overall shape completely preserves the crown, waist, and pavilion of the diamond. After electroplating it with rhodium into white, it is embedded in gold, presenting a dazzling diamond like luster. Dot diamonds add the charm of sparkling diamond light and shadow reflection to traditional gold products. It combines the luxury of gold with the brilliance of diamonds, bringing unprecedented new experiences to the new generation of consumers in gold products.

Low-temperature enamel

The main component of the glaze is liquid epoxy resin material, which only needs to be baked at a low temperature of 40-100 ° C. After baking, the color can solidify, and the process flow is relatively simple with low hardness.

High temperature roasted blue

The main component is silicate substances, which are repeatedly fired at a high temperature of 800 degrees. The process is cumbersome, the technology is high, the cost is relatively high, the hardness is high, it is resistant to oxidation, and it will not fade.

Comprehensive information and image sources: Zhaojin, Jewelry class, online, specific sources unknown

For communication and sharing only, thank you to the original author | If the editor's choice makes you feel inappropriate

Please contact us and we will delete and process it as soon as possible. Thank you very much!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque