As a leading CNC Machining service provider, EMAR specializes in high-precision 45# steel CNC machining solutions for various industrial sectors. Our advanced manufacturing capabilities ensure exceptional quality and dimensional accuracy for your critical components.

Why Choose 45# Steel for CNC Machining?

45# steel (AISI 1045) is a medium-carbon steel widely used in mechanical engineering due to its excellent strength-to-weight ratio, good machinability, and heat treatment properties. Our CNC machining processes can transform this material into precision parts with tight tolerances (up to ±.005mm) for applications requiring durability and wear resistance.

Our 45# Steel CNC Machining Capabilities

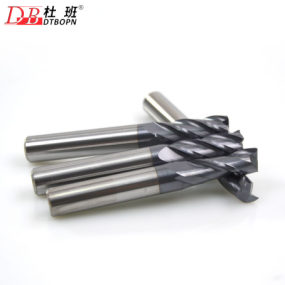

EMAR's facility features state-of-the-art 5-axis CNC machines that handle complex geometries in 45# steel, including:

- Precision turning and milling operations

- Drilling and tapping with high positional accuracy

- Surface grinding and finishing services

- Custom heat treatment integration

Quality Assurance in Every Process

We implement rigorous quality control measures throughout our CNC machining workflow, from material certification to final inspection. Our ISO 9001-certified processes guarantee that every 45# steel component meets your exact specifications and industry standards.

Visit EMAR's official website to explore our full range of CNC machining services and request a free project consultation today.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole