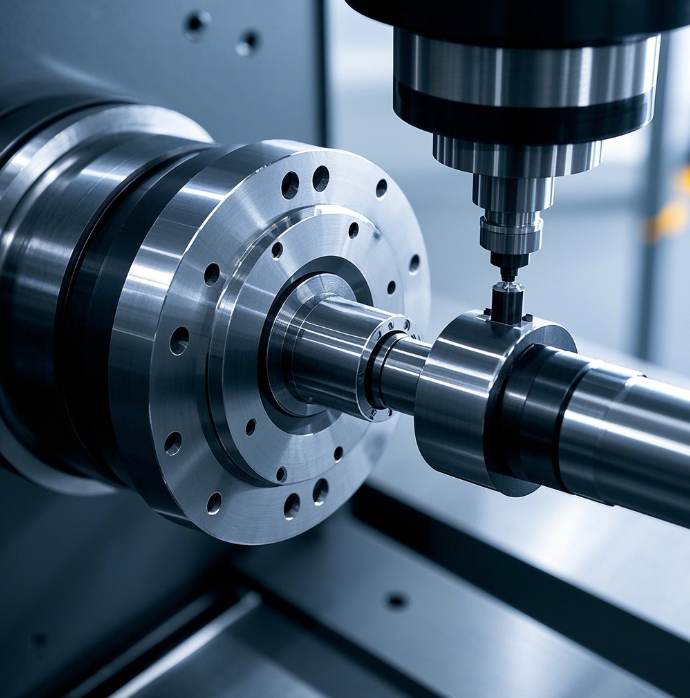

When it comes to precision manufacturing, selecting the right CNC turning service provider is critical for ensuring quality, efficiency, and cost-effectiveness. As a leading expert in CNC Machining, EMAR Company specializes in delivering high-performance solutions tailored to your specific needs. Here’s a comprehensive guide to help you make an informed decision.

Key Factors to Evaluate in a CNC Turning Service

1. Precision and Accuracy: Top-tier providers like EMAR utilize advanced CNC lathes with micron-level tolerances to meet stringent industry standards.

2. Material Expertise: Ensure the supplier handles diverse materials (e.g., aluminum, titanium, plastics) for versatile applications.

3. Scalability: Opt for partners capable of both prototyping and large-scale production to future-proof your supply chain.

Why EMAR Stands Out in CNC Machining

With ISO 9001-certified facilities and 15+ years of experience, EMAR offers:

- State-of-the-art multi-axis CNC turning centers for complex geometries

- Dedicated engineering support from design to post-processing

- Competitive lead times without compromising quality

Optimizing Your CNC Turning Project

Collaborate early with our technical team to:

- Select optimal tool paths and cutting parameters

- Minimize material waste through DFM analysis

- Implement automated inspection for consistent output

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole