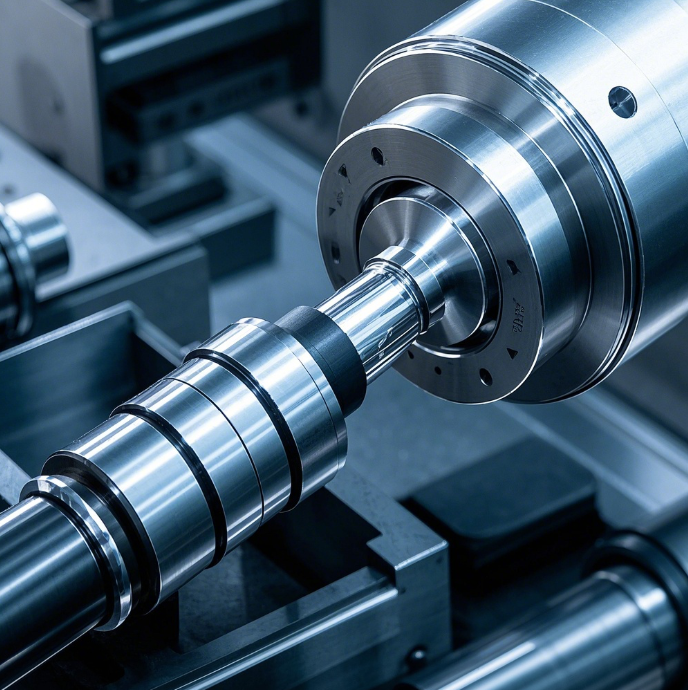

When sourcing CNC lathe machining services, obtaining precise quotes is critical for budget planning and supplier evaluation. As a professional CNC Machining provider, EMAR explains key factors affecting pricing and how to streamline the quoting process.

What Determines CNC Turning Service Costs?

1. Material Selection: Aluminum alloys typically cost 30-50% less than titanium or stainless steel machining due to tool wear and cycle time differences.

2. Part Complexity: Components requiring live tooling, multi-axis operations, or tight tolerances (±.01mm) increase programming and machining time.

3. Order Volume: Per-unit costs decrease significantly for production runs over 500 pieces due to optimized tool paths and reduced setup time.

EMAR's Transparent Quoting Process

Our 3-step quotation system ensures no hidden costs:

1. Technical Review: Engineers analyze your 3D models (STEP/IGES format preferred) within 4 business hours

2. Process Planning: We identify the most cost-effective machining strategy using our Okuma and DMG MORI multitasking lathes

3. Competitive Pricing: Quotes include material certification, surface treatment options, and logistics solutions

Why Global Clients Choose EMAR

• 40% Faster Lead Time: Automated tool changers and robotic loading systems enable 5-day standard delivery

• ISO 9001 Certified Quality: First-article inspection reports and CMM measurements included with every order

• Dedicated Project Management: English-speaking technical support available 24/5 via our online portal

Request your customized CNC turning quote today at www.sjt-ic.com with instant DFM feedback.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole