Selecting the right CNC Machining factory is critical for ensuring high-quality parts, cost efficiency, and reliable production timelines. As a professional CNC service provider, EMAR (www.sjt-ic.com) specializes in delivering precision-machined components for industries ranging from aerospace to automotive. This guide explores key factors to consider when evaluating a CNC machining supplier.

1. Technical Capabilities and Equipment

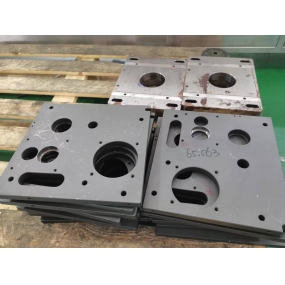

A top-tier CNC machining factory should possess advanced multi-axis machines (3/4/5-axis), CAD/CAM software integration, and metrology tools for quality control. EMAR's facility features Swiss-type lathes and vertical machining centers capable of ±.005mm tolerances.

2. Material Expertise and Certifications

Verify the manufacturer's experience with your required materials (aluminum, titanium, plastics) and industry certifications like ISO 9001:2015. Our team at EMAR has processed over 200 material grades with full traceability documentation.

3. Quality Assurance Processes

Reliable factories implement rigorous inspection protocols including CMM measurement, surface roughness testing, and first-article inspection. EMAR maintains a 99.2% on-time delivery rate with zero critical defects in the past 12 months.

4. Value-Added Services

Look for suppliers offering design-for-manufacturability (DFM) feedback, secondary operations (anodizing, plating), and flexible order quantities. EMAR provides complete turnkey solutions from prototyping to mass production.

When comparing CNC machining factories, prioritize technical competence over price alone. EMAR combines German-engineered equipment with 15+ years of machining expertise to deliver precision components that meet your exact specifications. Contact our engineering team for a free project evaluation today.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque