In modern manufacturing, 4-axis CNC Machining has become an essential technology for producing complex components with unmatched precision. As EMAR, we specialize in delivering advanced CNC solutions that meet the most demanding industry standards.

What is 4-Axis CNC Machining?

4-axis CNC machining adds a rotational movement (typically around the X-axis) to the traditional three linear axes, enabling the production of intricate geometries without multiple setups. This technology significantly reduces production time while improving accuracy for parts requiring multi-sided machining.

Key Advantages of Our 4-Axis CNC Services

1. Complex Geometry Handling: Machine undercuts, curved surfaces, and angular features in single setup

2. Enhanced Precision: Maintain tight tolerances (±.01mm) across multiple part faces

3. Cost Efficiency: Reduce labor costs and material waste through optimized machining strategies

4. Material Versatility: Process metals, plastics, and composites with equal precision

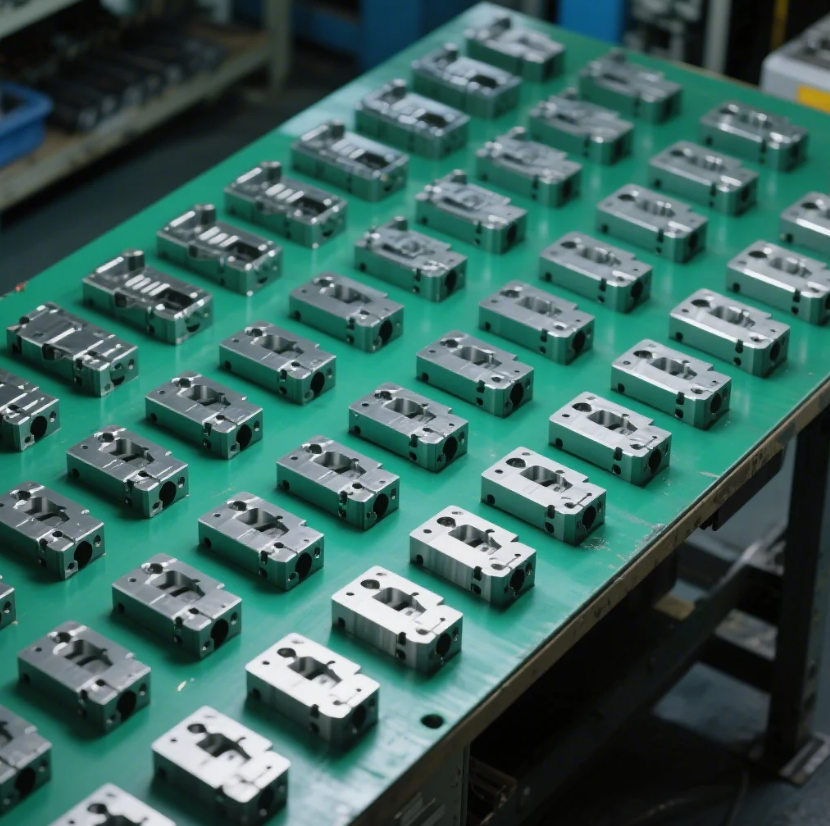

EMAR's 4-Axis CNC Capabilities

Our facility features state-of-the-art 4-axis machining centers equipped with:

- High-speed spindles (up to 15,000 RPM)

- Advanced tool changers (30+ tools capacity)

- Real-time monitoring systems

- CAD/CAM integration for seamless production

From prototyping to full-scale production, EMAR delivers 4-axis CNC machining solutions that combine German engineering precision with competitive pricing. Contact our technical team today to discuss your project requirements.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque