Selecting the ideal CNC Machining factory is crucial for manufacturing high-quality precision components. As an experienced CNC technical specialist at EMAR, I'll guide you through the key considerations when partnering with a machining parts supplier.

Technical Capabilities of Top CNC Factories

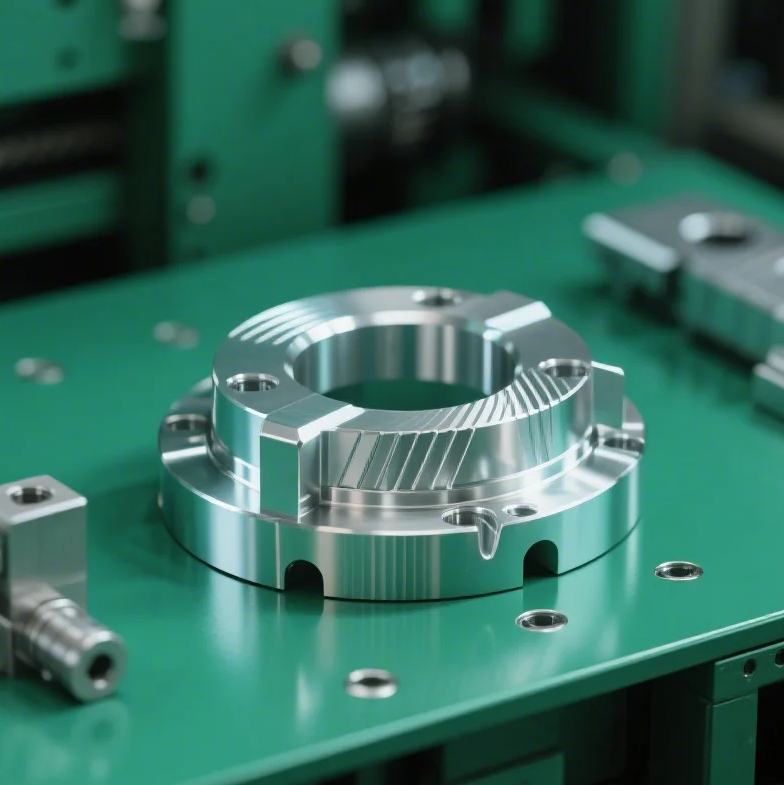

Premium CNC machining facilities like EMAR should offer 3-5 axis milling, turning, and multi-axis machining capabilities. Our factory maintains ±.005mm tolerance standards with advanced quality control systems.

Material Expertise for Industrial Components

A competent parts manufacturer must handle diverse materials including aluminum, stainless steel, titanium, and engineering plastics. We provide material selection guidance based on application requirements.

Quality Assurance Processes

Reliable CNC partners implement rigorous inspection protocols with CMM measurement, surface roughness testing, and full documentation. EMAR's ISO 9001 certified system ensures consistent part quality.

Production Scalability Considerations

Evaluate the supplier's capacity for both prototyping and volume production. Our flexible manufacturing setup accommodates from single prototypes to 50,000+ unit batches.

Value-Added Services

Top-tier providers offer design optimization, finishing services, and assembly solutions. EMAR's engineering team assists with DFM analysis to reduce costs and improve manufacturability.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque