Understanding Heat Sink CNC Machining

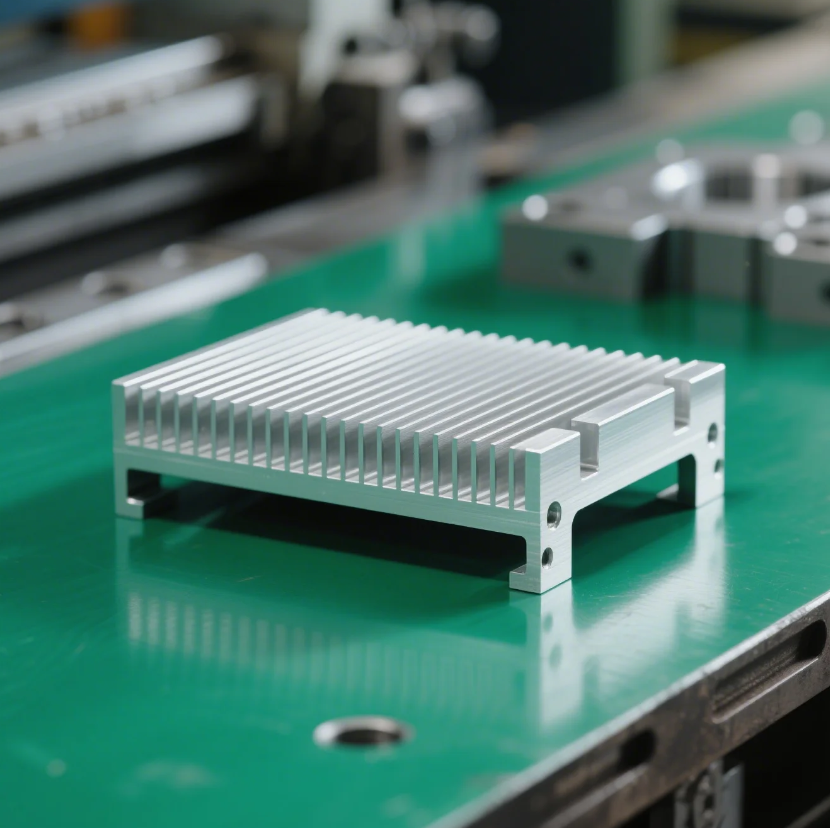

Heat sinks are critical components in electronic devices, designed to dissipate heat and ensure optimal performance. CNC machining is a highly precise and efficient method for producing heat sinks with complex geometries and tight tolerances. At EMAR, we specialize in manufacturing high-quality heat sinks using advanced CNC technology, catering to industries such as aerospace, automotive, and electronics.

The CNC Machining Process for Heat Sinks

The production of heat sinks via CNC machining involves several key steps:

- Material Selection: Common materials include aluminum (for lightweight and excellent thermal conductivity) and copper (for superior heat dissipation).

- CAD Design: Engineers create a detailed 3D model to define the heat sink's fins, base thickness, and other critical features.

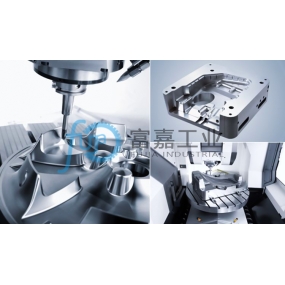

- CNC Milling: High-speed CNC mills carve out the heat sink's structure from a solid block, ensuring precision in fin spacing and surface flatness.

- Surface Finishing: Processes like anodizing or plating enhance corrosion resistance and thermal performance.

Why Choose EMAR for Your Heat Sink CNC Machining?

EMAR stands out as a trusted CNC machining manufacturer for heat sinks due to:

- Precision Engineering: Our state-of-the-art CNC machines achieve tolerances as tight as ±.01mm.

- Custom Solutions: We tailor heat sink designs to meet specific thermal management needs.

- Fast Turnaround: Rapid prototyping and mass production capabilities reduce lead times.

- Quality Assurance: Rigorous testing ensures every heat sink meets industry standards.

Applications of CNC-Machined Heat Sinks

From LED lighting to power electronics, CNC-machined heat sinks are vital in:

- Computer CPUs and GPUs

- Telecommunication equipment

- Electric vehicle battery systems

Partner with EMAR for reliable, high-performance heat sink solutions. Visit our website https://www.sjt-ic.com/ to explore our CNC machining services today!

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque