In modern manufacturing, nut CNC custom machining plays a pivotal role in delivering high-precision components for industries ranging from aerospace to automotive. At EMAR, we specialize in providing tailored CNC Machining services that meet the most demanding specifications.

What is Nut CNC Custom Machining?

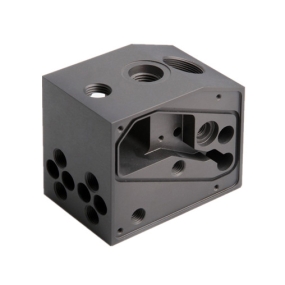

Nut CNC custom machining refers to the process of using computer-controlled machines to manufacture nuts with exact dimensions, thread patterns, and material properties. This method ensures unmatched accuracy and repeatability compared to traditional manufacturing techniques.

Key Advantages of Our Nut CNC Machining Services

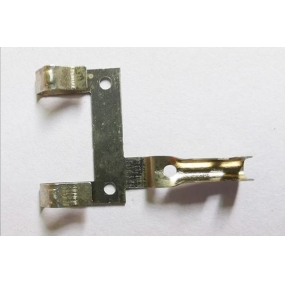

1. Material Versatility: We work with stainless steel, titanium, brass, and specialty alloys

2. Tight Tolerance Capability: ±.005mm precision for critical applications

3. Custom Thread Profiles: ACME, UN, metric, and proprietary designs

4. Surface Treatment Options: Anodizing, plating, passivation, and more

EMAR's Manufacturing Process

Our CNC machining workflow includes:

- CAD/CAM programming for optimal tool paths

- Multi-axis machining for complex geometries

- Rigorous quality control with CMM verification

- Post-processing and protective packaging

Industries We Serve

Our custom machined nuts are essential components for:

• Robotics and automation systems

• Heavy equipment manufacturing

• Energy and power generation

• Medical device assembly

• Defense and military applications

Why Choose EMAR for Your Nut Machining Needs?

With 15+ years of CNC machining expertise, EMAR offers:

- ISO 9001:2015 certified production facilities

- 24/7 project support from our engineering team

- Competitive pricing with fast turnaround times

- Complete confidentiality and IP protection

Contact us today at www.sjt-ic.com to discuss your specific nut machining requirements. Our technical team will provide expert guidance from design to delivery.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque