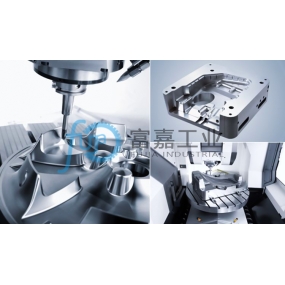

Understanding CNC Aluminum Alloy Machining

CNC aluminum alloy machining is a precision manufacturing process that uses computer numerical control (CNC) machines to shape aluminum alloy materials into desired components. As a leading provider in the industry, EMAR Company specializes in delivering high-quality CNC Machining services for various aluminum alloys, including 6061, 7075, and 2024 series.

The Advantages of CNC Machining for Aluminum Alloys

Aluminum alloys are widely used in aerospace, automotive, electronics, and other industries due to their excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. Our CNC machining process ensures precise dimensional accuracy, tight tolerances (up to ±.005mm), and superior surface finishes for aluminum components.

Key Steps in Our CNC Aluminum Machining Process

1. Material Selection: We help clients choose the most suitable aluminum alloy for their specific application requirements.

2. CAD/CAM Programming: Our engineers create optimized tool paths for maximum efficiency and precision.

3. Machining Operations: Including milling, turning, drilling, and tapping with our advanced CNC machines.

4. Quality Inspection: Using CMM and other precision measuring instruments to verify all specifications.

5. Surface Treatment: Optional anodizing, polishing, or powder coating for enhanced durability and appearance.

Why Choose EMAR for Your Aluminum CNC Machining Needs

With years of experience in CNC aluminum alloy machining, EMAR Company offers:

- State-of-the-art CNC machining centers with multi-axis capabilities

- Strict quality control systems certified to ISO 9001 standards

- Fast turnaround times without compromising quality

- Competitive pricing for both prototyping and mass production

- Comprehensive engineering support from design to final production

Applications of CNC Machined Aluminum Parts

Our precision-machined aluminum components serve various industries, including:

- Aerospace structural parts and brackets

- Automotive engine components and housings

- Electronic enclosures and heat sinks

- Medical equipment parts requiring lightweight and sterile surfaces

- Robotics and automation system components

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque