Selecting the right CNC Machining factory is critical for ensuring precision, efficiency, and cost-effectiveness in your manufacturing projects. As a professional CNC machining service provider, EMAR Company specializes in delivering high-quality CNC machining solutions tailored to meet diverse industrial needs. This guide will help you evaluate key factors when choosing a reliable partner.

Key Considerations for Selecting a CNC Machining Factory

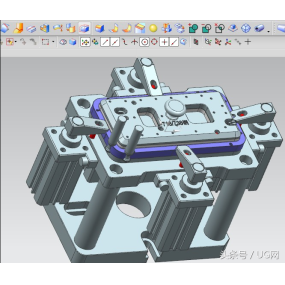

1. Technical Capabilities: Assess the factory's equipment portfolio (3/4/5-axis machines), material compatibility (aluminum, steel, titanium, plastics), and certifications (ISO 9001, AS910).

2. Quality Assurance: Look for factories with rigorous inspection processes (CMM, surface roughness testers) and documented quality control protocols.

3. Production Capacity: Verify their ability to handle your project volume – from prototyping to mass production with consistent quality.

Why EMAR Stands Out Among CNC Machining Factories

With 15+ years of experience, EMAR Company combines advanced CNC machining technologies with engineering expertise to deliver:

- ±.005mm machining accuracy

- 50+ metal/plastic material options

- Fast-turnaround prototyping (72-hour service)

- DFM (Design for Manufacturing) support

Industry-Specific CNC Machining Solutions

We serve multiple sectors including:

• Aerospace: Complex turbine components

• Automotive: High-volume precision parts

• Medical: FDA-compliant surgical instruments

• Electronics: Micro-machined enclosures

Making the Right Decision

Request samples, evaluate communication responsiveness, and compare pricing structures. EMAR offers free project consultations at www.sjt-ic.com with transparent quotations within 24 hours.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque