As a leading CNC precision machining supplier, EMAR specializes in delivering high-quality metal components for industries ranging from aerospace to medical devices. Our advanced manufacturing capabilities ensure tight tolerances (±.005mm), superior surface finishes (Ra .2μm), and cost-effective solutions for both prototyping and mass production.

Why Choose EMAR for Your Metal CNC Machining Needs?

With 15+ years of experience in precision metal machining, we offer:

- 50+ CNC machines (5-axis, Swiss-type, and milling-turning centers)

- Material expertise: Aluminum, Titanium, Stainless Steel, Brass, and Exotic Alloys

- ISO 9001:2015 certified quality control with CMM inspection

- Just-in-time delivery with 98% on-time rate

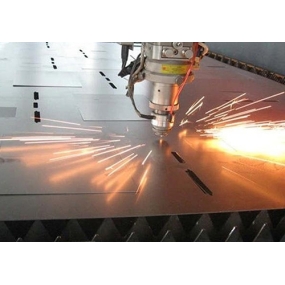

Our Metal CNC Machining Process

The metal CNC precision machining workflow at EMAR includes:

- DFM analysis to optimize your design for manufacturability

- Material selection and verification

- Precision machining with real-time monitoring

- Post-processing (anodizing, plating, heat treatment)

- 100% quality inspection before shipment

Industries We Serve

Our CNC machined metal components are critical to:

- Aerospace: Engine parts, landing gear components

- Medical: Surgical instruments, implantable devices

- Automotive: Transmission systems, fuel injection parts

- Electronics: Heat sinks, connector housings

Get a Free Project Review Today

Submit your CAD files to EMAR's engineering team for instant DFM feedback and competitive quotation. We maintain 24/7 production capacity to meet your most demanding deadlines without compromising precision.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque