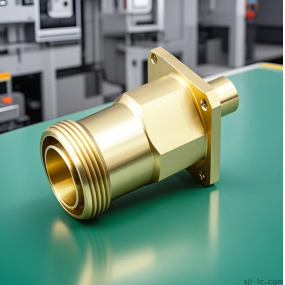

When it comes to aluminum plate CNC Machining, EMAR stands as a trusted partner for industries requiring high-precision, durable, and customized metal components. Our advanced CNC technology ensures exceptional accuracy and efficiency for your prototyping or mass production needs.

Why Choose CNC Machining for Aluminum Plates?

Aluminum is favored for its lightweight, corrosion resistance, and excellent machinability. Our CNC machining processes transform raw aluminum plates into complex parts with tight tolerances (up to ±.005mm), perfect for aerospace, automotive, electronics, and industrial applications.

EMAR's Aluminum CNC Machining Capabilities

Our facility features state-of-the-art 3/4/5-axis CNC machines that handle:

- Plate sizes up to 200×800×300mm

- Surface finishes from rough machining to mirror polishing (Ra.2)

- Secondary processes: anodizing, powder coating, laser engraving

Quality Assurance You Can Trust

Every custom aluminum part undergoes rigorous inspection with CMM, profilometers, and hardness testers to meet ISO 9001 and AS910 standards. We provide full material certifications and inspection reports with each order.

Streamlined Production Workflow

From your CAD files to finished parts, our process includes:

- Design for Manufacturability (DFM) analysis

- Optimal toolpath programming

- Precision machining with real-time monitoring

- Comprehensive quality control

- Careful packaging and logistics

Request a free quote today at www.sjt-ic.com or contact our engineering team to discuss your specific aluminum machining requirements. EMAR delivers precision, reliability, and on-time performance for every project.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque