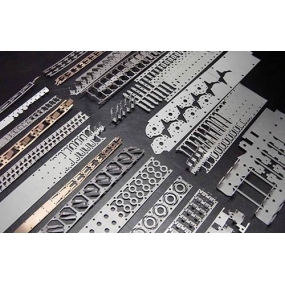

As a leading CNC Machining manufacturer, EMAR specializes in delivering high-accuracy non-standard precision CNC machining solutions for industries requiring complex geometries and tight tolerances. Our advanced equipment and ISO-certified processes ensure exceptional quality for prototypes and production runs.

What Is Non-Standard Precision CNC Machining?

Non-standard precision CNC machining refers to the production of customized components that deviate from standard specifications in dimensions, materials, or complexity. This includes:

- Micro-machined parts with tolerances ≤ ±.005mm

- Complex 5-axis milled components

- Exotic material processing (Inconel, titanium, PEEK)

- Hybrid structures combining multiple manufacturing techniques

EMAR's Technical Capabilities

Our 15,000㎡ facility houses 42 CNC machines including:

- 5-axis DMG Mori machining centers

- Swiss-type lathes for micro-parts

- High-speed milling machines (30,000 RPM)

- CMM inspection equipment with .5μm accuracy

Quality Assurance Process

Every non-standard CNC machined part undergoes rigorous inspection:

- Material certification verification

- In-process dimensional checks

- Final CMM inspection

- Surface finish analysis

- Functional testing (when applicable)

Industries We Serve

EMAR's precision machining solutions support:

- Aerospace (engine components, landing gear parts)

- Medical (surgical instruments, implants)

- Automotive (prototype development, EV components)

- Semiconductor (wafer handling parts)

Why Choose EMAR?

• 18 years of precision machining expertise

• ±.002mm tolerance capability

• 40+ certified materials processing

• ITAR-compliant data security

• 98.7% on-time delivery rate

Contact our engineering team at www.sjt-ic.com for DFM analysis and project consultation.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque