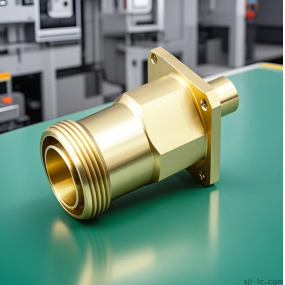

When sourcing metal CNC Machining services, understanding cost drivers is critical for procurement managers and engineers. As a trusted CNC machining manufacturer, EMAR breaks down key pricing factors and our competitive advantages in this comprehensive guide.

What Determines Metal CNC Machining Costs?

1. Material Selection: Aerospace aluminum (6061/7075) costs 20-30% less than titanium alloys. EMAR maintains an in-house inventory of 50+ metal grades to optimize pricing.

2. Part Complexity: A simple bracket requires 2-3 machining operations vs. 5-7 steps for turbine components with ±.005mm tolerances.

3. Order Volume: Batch production reduces per-unit costs by 40-60% through optimized tool paths and fixture sharing.

EMAR's Value-Added Cost Control Strategies

• DFM Analysis: Our engineers review your CAD files to suggest design modifications that reduce machining time by 15-25% without compromising functionality.

• Multi-Axis Efficiency: 5-axis simultaneous machining eliminates secondary operations, cutting labor costs by 30% for complex geometries.

• Smart Tooling: Proprietary tool life monitoring extends carbide end mill lifespan by 35%, reducing consumable expenses.

Why Choose EMAR for Your Metal CNC Projects?

With 12 years of precision CNC machining expertise, we combine German-engineered DMG Mori equipment (.001mm repeatability) with ISO 9001-certified processes. Our clients in automotive and medical sectors consistently achieve 98% on-time delivery with zero quality incidents.

Request a competitive quote within 24 hours by uploading your technical drawings to www.sjt-ic.com or contacting our engineering team directly.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque