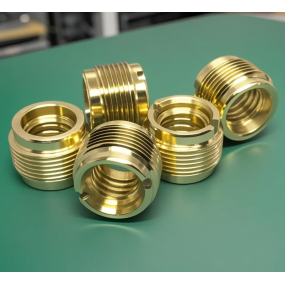

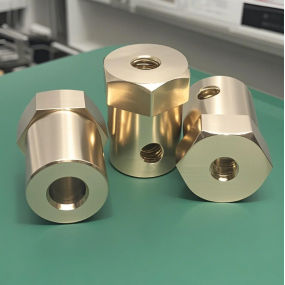

As a leading CNC precision machining supplier, EMAR Company specializes in delivering high-quality copper components for industries requiring tight tolerances and superior surface finishes. Our advanced manufacturing capabilities ensure reliable solutions for aerospace, electronics, and automotive applications.

Why Choose Copper for CNC Machining?

Copper offers exceptional electrical conductivity, thermal resistance, and corrosion durability, making it ideal for heat exchangers, electrical connectors, and RF shielding components. Our precision machining processes maintain these material properties while achieving ±.005mm accuracy.

EMAR's Copper Machining Capabilities

We utilize 5-axis CNC mills and Swiss-type lathes equipped with diamond-coated tools to handle copper's unique machining challenges:

- Micro-machining for components under 1mm

- Mirror finishes with Ra .2μm surface quality

- Prototype to mass production (100,000+ units/month)

Quality Assurance Process

Every copper part undergoes rigorous inspection using CMM (Coordinate Measuring Machines) and conductivity testing. Our ISO 9001-certified system guarantees traceability and consistent supply chain reliability.

Contact EMAR at www.sjt-ic.com for your copper machining projects - from design support to just-in-time delivery.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque