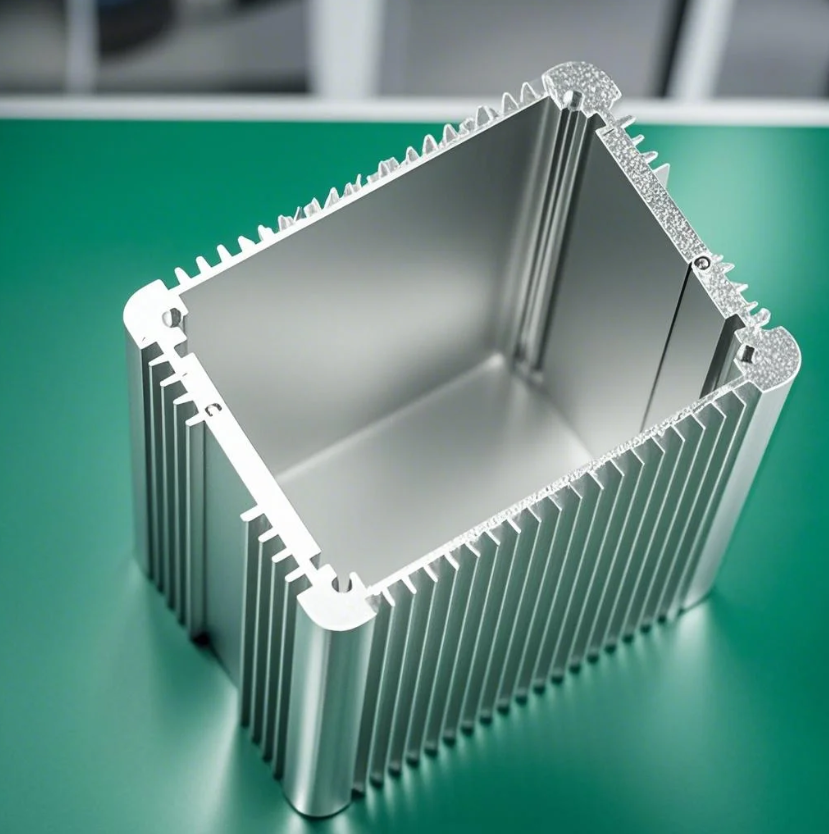

In the realm of modern manufacturing, CNC aluminum enclosure processing stands as a cornerstone for industries demanding high precision, durability, and aesthetic appeal. At EMAR, we specialize in delivering top-tier CNC Machining services tailored to meet the exacting standards of engineers, procurement managers, and business owners. This article delves into the intricacies of CNC aluminum enclosure processing, highlighting its benefits, applications, and why EMAR is your trusted partner for this critical service.

What is CNC Aluminum Enclosure Processing?

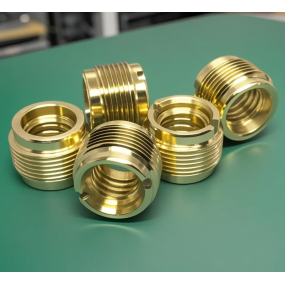

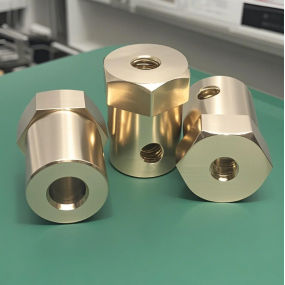

CNC aluminum enclosure processing involves the use of computer numerical control (CNC) machines to fabricate enclosures from aluminum materials. This process ensures unparalleled precision, allowing for the creation of complex geometries and tight tolerances that are essential for electronic, automotive, aerospace, and industrial applications. The enclosures produced are not only robust but also lightweight, corrosion-resistant, and thermally conductive, making them ideal for a wide range of uses.

Key Advantages of CNC Aluminum Enclosures

Choosing CNC aluminum enclosure processing offers numerous benefits:

- Precision and Accuracy: CNC machining guarantees exact dimensions and flawless finishes, critical for functional and aesthetic requirements.

- Durability: Aluminum's inherent strength and resistance to environmental factors ensure long-lasting performance.

- Customization: From intricate designs to specific dimensional needs, CNC processing accommodates bespoke solutions.

- Cost-Effectiveness: High efficiency and reduced material waste translate to competitive pricing without compromising quality.

Applications of CNC Aluminum Enclosures

CNC aluminum enclosures are ubiquitous across industries:

- Electronics: Housing for sensitive components requiring EMI shielding and heat dissipation.

- Automotive: Durable casings for control units and sensors.

- Aerospace: Lightweight yet sturdy enclosures for avionics and communication devices.

- Industrial Equipment: Protective shells for machinery operating in harsh environments.

Why Choose EMAR for Your CNC Aluminum Enclosure Needs?

At EMAR, we combine cutting-edge technology with decades of expertise to deliver superior CNC aluminum enclosure processing services. Our commitment to quality, timely delivery, and customer satisfaction sets us apart. Partner with us to experience seamless project execution from design to final product.

Explore our capabilities further at EMAR's official website and discover how we can elevate your next project with precision CNC machining solutions.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque