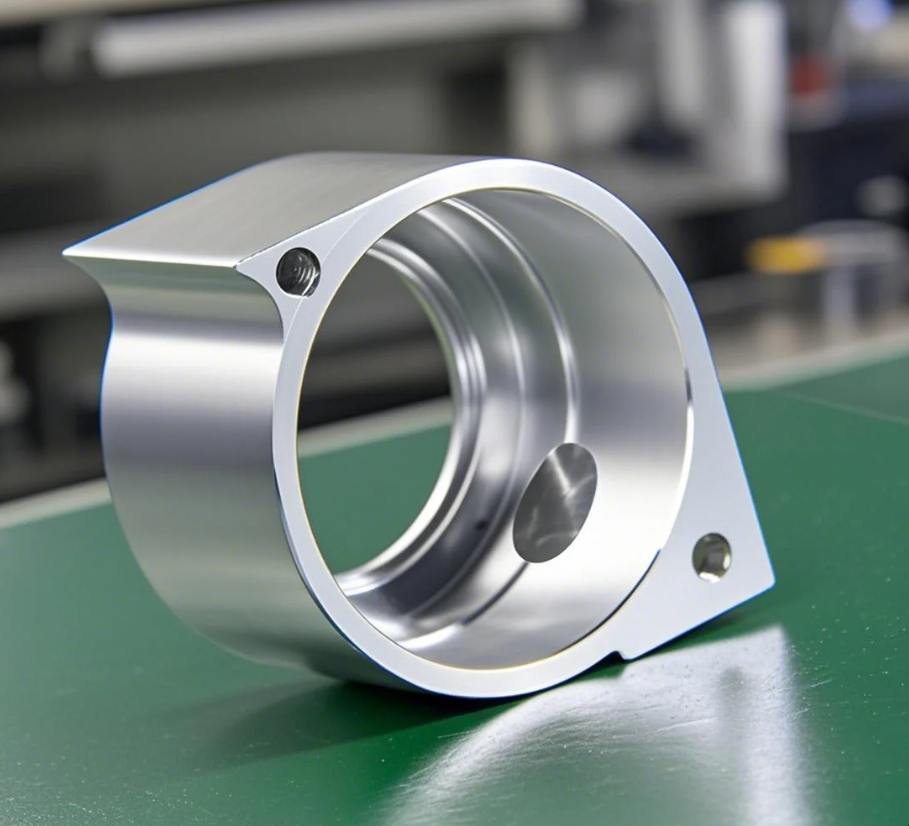

Understanding Aluminum Alloy CNC Machining

Aluminum alloy CNC machining is a precise manufacturing process that uses computer numerical control (CNC) machines to shape aluminum parts with exceptional accuracy. As a premier CNC machining service provider, EMAR specializes in transforming aluminum alloys into high-quality components for various industries, including aerospace, automotive, and electronics.

The Advantages of Aluminum for CNC Machining

Aluminum alloys are preferred in CNC machining due to their excellent machinability, strength-to-weight ratio, and corrosion resistance. Our CNC machining experts at EMAR leverage these properties to create parts with tight tolerances and superior surface finishes. The material's thermal conductivity also makes it ideal for heat dissipation applications.

Our Aluminum CNC Machining Capabilities

EMAR's state-of-the-art CNC machining centers can handle all aluminum grades, from 6061 to 7075. We offer:

- 3-axis to 5-axis CNC milling

- CNC turning and swiss machining

- High-speed machining for complex geometries

- Secondary operations (anodizing, painting, etc.)

Quality Assurance in Every Process

At EMAR, we implement strict quality control measures throughout the aluminum CNC machining process. From material inspection to final dimensional verification, our quality management system ensures every part meets or exceeds customer specifications and industry standards.

Applications of CNC Machined Aluminum Parts

Our precision-machined aluminum components serve critical functions across industries:

- Aerospace structural components

- Automotive engine parts

- Electronic enclosures and heat sinks

- Medical device components

- Industrial machinery parts

Why Choose EMAR for Your Aluminum CNC Machining Needs

With years of experience in CNC machining, EMAR combines technical expertise with advanced manufacturing capabilities to deliver superior aluminum parts. Our competitive pricing, fast turnaround times, and commitment to customer satisfaction make us the preferred partner for businesses worldwide.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque