In today's competitive manufacturing landscape, CNC metal parts machining stands as a cornerstone of precision engineering. As a leading provider in this field, EMAR delivers exceptional quality and reliability for industries ranging from aerospace to automotive. This article explores the critical aspects of metal parts machining and why partnering with an expert like EMAR ensures superior results.

What is CNC Metal Parts Machining?

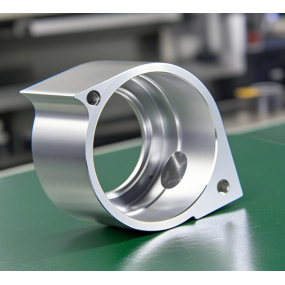

CNC Machining for metal parts involves computer-controlled processes to shape raw metal materials into precise components. This technology enables the production of complex geometries with tight tolerances (often within ±.005mm), making it ideal for critical applications where precision is paramount.

Key Advantages of Our CNC Metal Machining Services

EMAR's advanced capabilities offer numerous benefits:

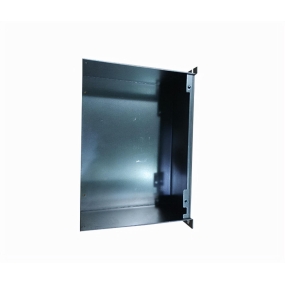

- Material Versatility: We machine aluminum, stainless steel, brass, titanium, and exotic alloys

- Precision Engineering: Our 5-axis CNC machines achieve tolerances to ±.002mm

- Scalable Solutions: From prototypes to high-volume production (100,000+ units)

- Surface Finish Options: Including anodizing, plating, powder coating, and more

Industries We Serve with CNC Machined Metal Parts

Our CNC metal components support diverse sectors:

- Automotive: Engine components, transmission parts, brackets

- Aerospace: Structural elements, landing gear components

- Medical: Surgical instruments, implantable devices

- Electronics: Enclosures, heat sinks, connectors

Why Choose EMAR for Your Metal Parts Machining Needs?

EMAR distinguishes itself through:

- ISO 9001:2015 certified quality management

- DFM (Design for Manufacturing) analysis with every project

- 30+ years of combined engineering expertise

- Competitive pricing with 15-30% cost savings versus industry averages

- Rapid turnaround (as quick as 24 hours for prototypes)

For your next metal parts project, trust EMAR's CNC machining excellence. Visit our website at https://www.sjt-ic.com/ to request a quote or discuss your specific requirements with our engineering team.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque