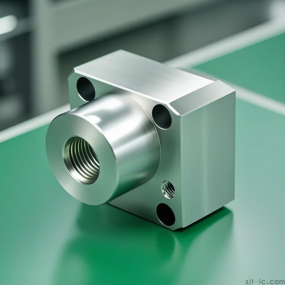

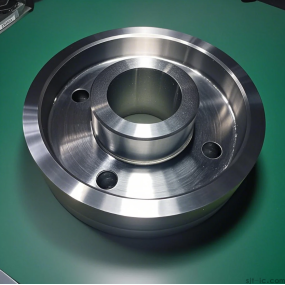

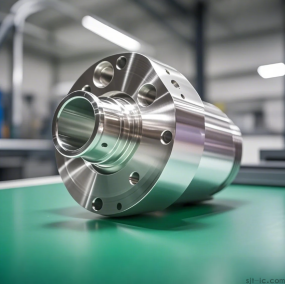

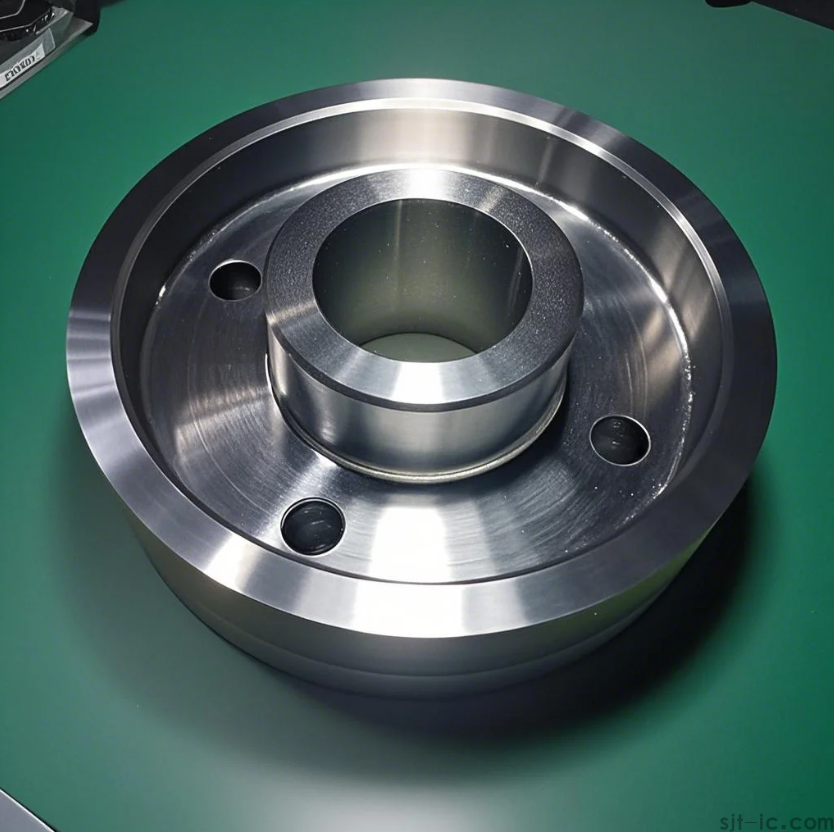

As a professional stainless steel CNC Machining service provider, EMAR Company specializes in delivering high-precision components for industries ranging from aerospace to medical equipment. Our advanced CNC technology ensures exceptional accuracy, durability, and surface finish for even the most complex stainless steel parts.

Why Choose Stainless Steel for CNC Machining?

Stainless steel is one of the most popular materials for CNC machining due to its excellent corrosion resistance, strength, and aesthetic appeal. Common grades we machine include 303, 304, 316, and 17-4 PH, each offering unique properties for different applications. Our CNC machining processes can handle all these variants with tight tolerances up to ±.005mm.

Our Stainless Steel CNC Machining Capabilities

EMAR Company offers comprehensive machining services for stainless steel components:

- Precision milling and turning

- Multi-axis machining (3-axis, 4-axis, and 5-axis)

- Micro-machining for small, intricate parts

- Surface finishing (polishing, passivation, plating)

- Prototype to mass production

Quality Assurance in Every Step

We implement rigorous quality control measures throughout our stainless steel machining process. Our facility is equipped with advanced inspection equipment including CMMs, optical comparators, and surface roughness testers to ensure every part meets your exact specifications and industry standards.

Applications of Our Machined Stainless Steel Parts

Our precision-machined stainless steel components serve critical functions in:

- Medical devices and surgical instruments

- Food processing equipment

- Automotive and aerospace components

- Marine hardware

- Semiconductor manufacturing equipment

At EMAR Company, we combine cutting-edge CNC technology with extensive material expertise to deliver stainless steel parts that exceed expectations. Contact us today to discuss your project requirements and receive a competitive quote.

```

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque